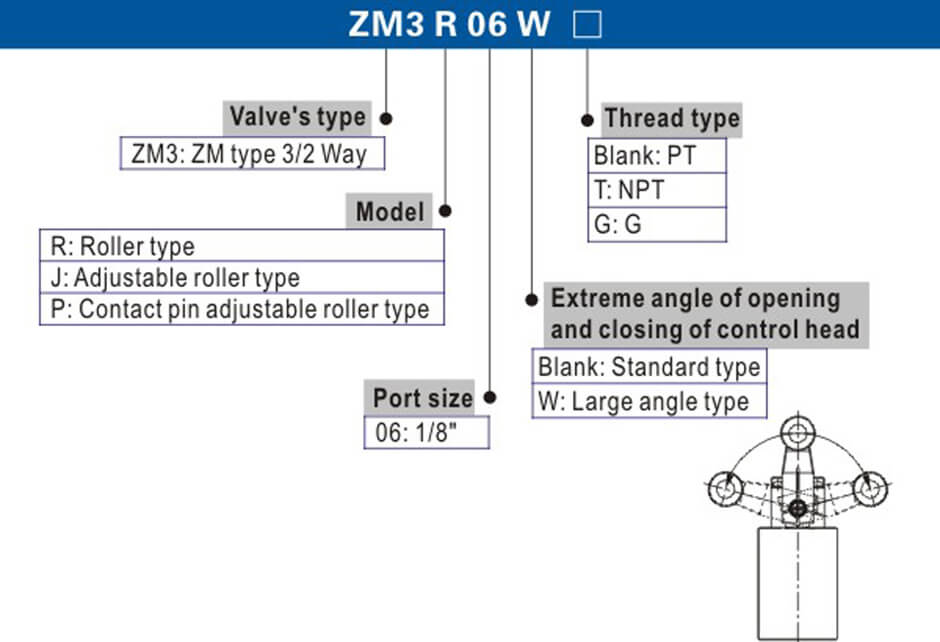

产品名称:ZM3系列电磁阀 产品型号:ZM3P06 ZM3P06W ZM3J06 ZM3J06W ZM3R06 ZM3R06W 类型:电磁阀,气控阀 品牌: 亚德客(AiRTAC) 工作介质: 空气 位置数:三口二位 作动方式: 外部控制直动式

| 型号: | ZM3R | ZM3J | ZM3P |

| 工作介质: | 空气(经40μm以上滤网过滤) | ||

| 作动方式: | 外部控制直动式 | ||

| 接管口径: | PT1/8 | ||

| 有效截面积: |

6.0mm²(Cv=0.34) |

||

| 位置数: | 三口两位 | ||

| 使用压力范围: | 0.10~0.8MPa(-1~10bar)(-15~145psi) | ||

| 保证耐压力: | 1.5MPa(15bar)(215psi) | ||

| 工作温度(℃) | -20~70 | ||

| 本体材质: | 铝合金 | ||

| 润滑: |

不需要 |

||

①接管牙型有NPT、G牙可供选择;

②如有加油润滑,中途不可停止,建议润滑油为ISO VG32或同级用油。

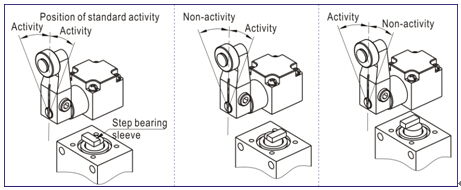

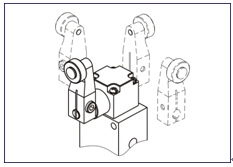

1.The activity direction could be changed(Only adapt to standard type, large angle type unavailable)

2.The rolling wheel could be installed at the inside of leverage

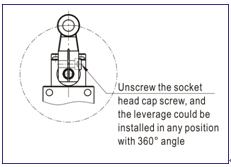

3.Installation position of leverage could be changed

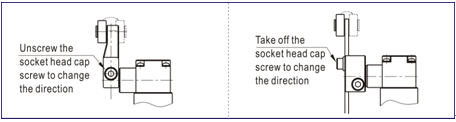

4. Direction of head part could be changed

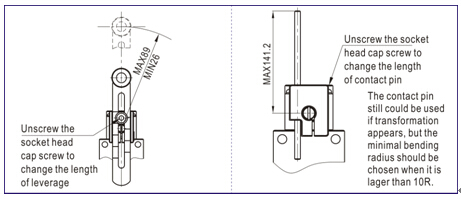

5. Length of contact pin could be changed

Installation & Usage:

1.Check whether the components have been damaged during transportation before installing and using.

2.Pay attention to whether the flow direction of air (notice“→” direction) and thread type are correct.

3.Please notice whether installation condition accords with technical requirements (such as “working pressure”and“applied temperature range”);

4.Take measure to avoid vibration and frozen.

5.Before using the fittings and tubes make sure they are clean. When connecting tofittings, be sure the PTFE Thread Seal Tape is used correctly.

6.Keep the dust away. The dust cover shall be installed in intake and outlet when the device is dismantled and stored.