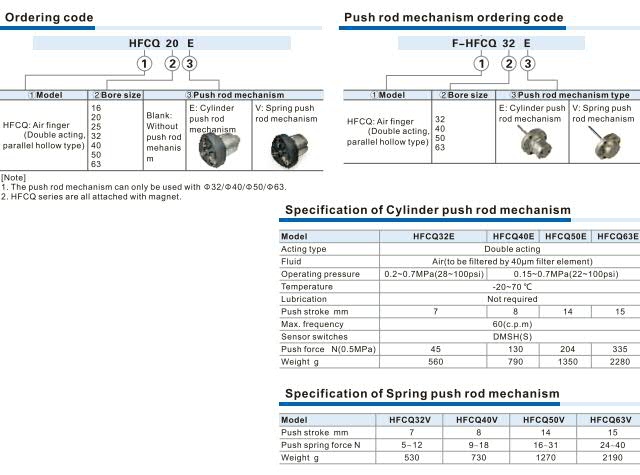

产品名称:F-HFCQ系列防尘气动手指 产品型号:F-HFCQ32E F-HFCQ40E F-HFCQ50E F-HFCQ63E F-HFCQ32V F-HFCQ40V F-HFCQ50V F-HFCQ63V 品牌: 亚德客(AirTAC) 工作介质: 空气 作动方式: 复动型

规格:

|

内径(mm): |

16 | 20 | 25 | 32 | 40 | 50 | 63 |

|

作动型式: |

复动型 | ||||||

|

工作介质: |

空气(经40μm以上滤网过滤) | ||||||

| 使用压力范围: | 0.2~0.7MPa(28~100psi)(2.0~7.0bar) | 0.15~0.7MPa(22~100psi)(1.5~7.0bar) | |||||

| 工作温度(℃): | -20~70 | ||||||

| 给油: | 不需要 | ||||||

| 重复精度: | ±0.01mm | ||||||

| 重复使用频率: | 120(c.p.m) | 60(c.p.m) | |||||

| 所配感应开关: | CMSH、DMSH(S) | ||||||

| 接管口径: | M3x0.5 | M5x0.8 | |||||

| 通孔径:M5x0.8 | ∅3(+0~+0.04) | ∅3(+0~+0.04) | ∅4(+0~+0.048) | ∅6(+0~+0.04) | ∅10(+0~+0.068) | ∅12(+0~+0.07) | ∅16(+0~+0.07) |

| 选配推杆附件: | - |

气缸式、弹簧式 |

|||||

| 推杆附件接管: | - | M5x0.8 | |||||

1. The hollow tube can be matched with mechanism to achieve the blowing effect.

2. The jaws and piston rods are made of high-grade stainless steel, which has high strength, corrosion resistance and small assembly cleearance, low shaking and high durability.

3. All series are equipped with a dust jacket, which can also be used in special occasions.

4. A positioning hole is attached to the bottom of the body, which can improve the precision and the consistency of repeated dismounting and positioning.

5. The tail end is equipped with a push rod mechanism for the push function.

6. The sensor grooves of each specification are shaed.

Installation & Usage:

1. Due to the abrupt changes, the circuit pressure is low, which will lead to the decrease of the gripping force and falling of the work-pieces. In order to avoid the harm to the human body and damage to the equipment, anti-dropping device must be equipped.

2. Don't use the air gripper under strong external force and impact force.

3. When install and fix the air gripper, avoid falling down, collision and damage.

4. When fixing the gripping jaw parts, don't twist the gripping jaw.

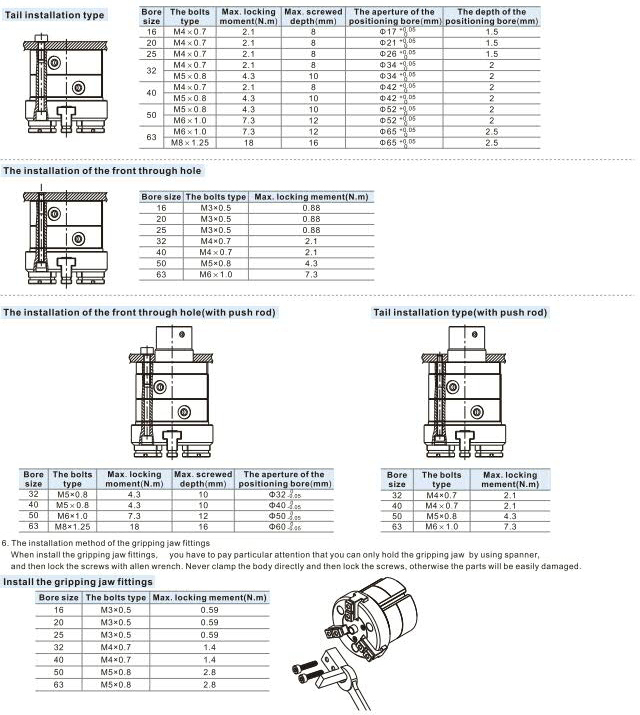

5. There are several kinds of installation method, and the locking torgue of fastening screw must be within the prescribed torque range shown in the below chart. If the locking torque is too large, it will cause the dysfunctional. If the locking torque is too small, it will cause the position deviation and fall.