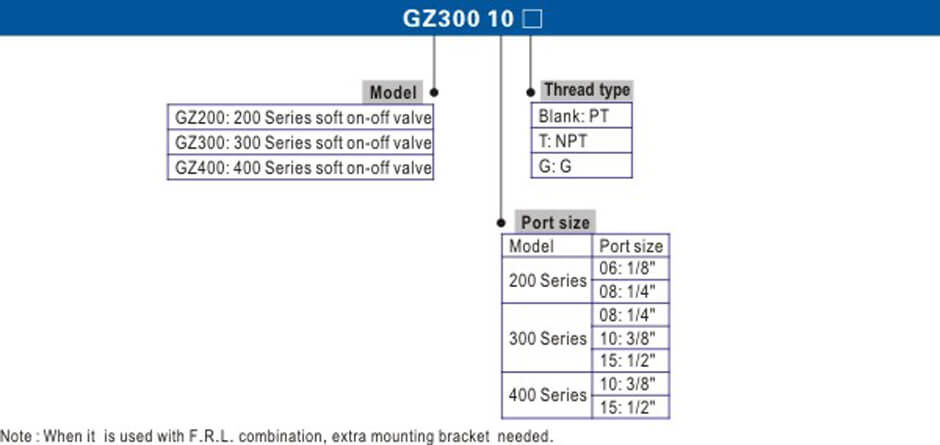

Product Name:GZ Series Air Control Preparation Unit Product Model:GZ200-06 GZ200-08 GZ300-08 GZ300-10 GZ300-15 GZ400-10 GZ400-15 Filtering Grade:40μm or 5μm Brand:AiRTAC Fluid: Air Max Supply Pressure:1.0MPa(145psi) Proof Pressure: 1.5MPa(215psi)

|

Model: |

GZ200-06 | GZ200-08 | GZ300-08 | GZ300-10 | GZ300-15 | GZ400-10 |

GZ400-15 |

|||

| Fluid: | Air | |||||||||

| Port Size: | PT1/8 | PT1/4 | PT1/4 | PT3/8 | PT1/2 | PT3/8 |

PT1/2 |

|||

| Exhuast Port Size: | 1/4" | 3/8" |

1/2" |

|||||||

| Acting Type: | Manual | |||||||||

| Valve Type: |

3 Port 2 Way |

|||||||||

| Pressure Range: | 0~0.9MPa(0~130psi) | |||||||||

| Proof Pressure: | 1.5MPa(215psi) | |||||||||

| Temperature Range: | -20~70℃ | |||||||||

| Capacity of Drain Bowl: | 90° | |||||||||

| Weight: | 135g | 360g | 680g | 1440g | ||||||

①PT thread, NPT thread and G thread are available.

2.This valve can be used as manual 3/2 way valve.

3.Visual indication marked EXH/SUP.

4.This valve meets the standard on installation conducted by operator specified by OSHA (Occupational Safety & Health Administration). When the machinery is maintained and serviced, the purge valve (Safe on-off valve) for remaining pressure shall be used to eliminate the remaining pressure when the air source is cut off. Valve must be locked to prevent accidental operation by a third party during maintenance. This prevents accidental system pressurization & cylinder actuation which can result in injuries to the machine operator.

Installation & Usage:

1.Check whether the components have been damaged during transportation before installing and using.

2.Pay attention to whether the flow direction of air (notice “→” direction) and thread type are correct.

3.Please notice whether installation condition accords with technical requirements (such as “working pressure” and “applied temperature range”);

4.Avoid usage in an environment that exposes the filter and lubricator bowl through contact with Chlorine, solvent, aromatic essence, acid and alkali to avoid damage to the Filter and Lubricator bowl.

5.Regularly clean or change filter core. Lubricators and regulators shall be in descending order.

6.Keep the dust away. The dust cover shall be installed in intake and outlet when the device is dismantled and stored.

| GZ20006G | GZ30008G | GZ30008J | GZ30010JT | GZ30010 | GZ40015G |

| GZ20006T | GZ30008T | GZ30008JG | GZ30015G | GZ30015 | GZ40015T |

| GZ20006J | GZ20008JG | GZ30008JT | GZ30015T | GZ40010G | GZ40015J |

| GZ20006JG | GZ20008JT | GZ30010G | GZ30015J | GZ40010T | GZ40015JG |

| GZ20006JT | GZ20008 | GZ30010T | GZ30015JG | GZ40010J | GZ40015JT |

| GZ20008T | GZ20006 | GZ30010J | GZ30015JT | GZ40010JG | GZ40010 |

| GZ20008J | GZ20008G | GZ30010JG | GZ30008 | GZ40010JT | GZ40015 |