Product Name:GV Series Air Control Preparation Unit Product Model:GV200-06 GV200-08 GV300-08 GV300-10 GV300-15 Filtering Grade:40μm or 5μm Brand:AiRTAC Fluid: Air Max Supply Pressure:1.0MPa(145psi) Proof Pressure: 1.5MPa(215psi)

|

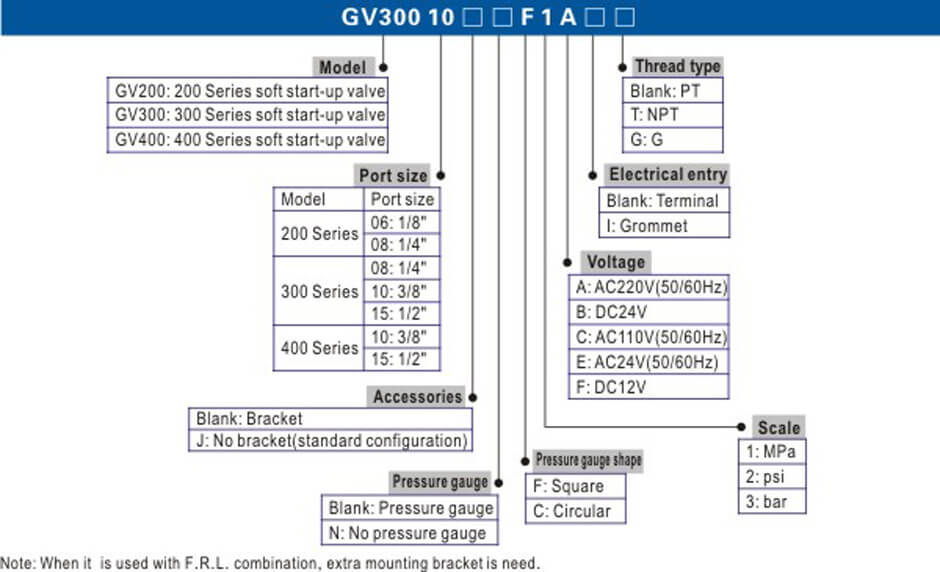

Model: |

GV200-06 | GV200-08 | GV300-08 | GV300-10 | GV300-15 | GV400-10 | GV400-15 | |||

| Fluid: | Air | |||||||||

| Port Size: | PT1/8 | PT1/4 | PT1/4 | PT3/8 | PT1/2 | PT3/8 |

PT1/2 |

|||

| Pressure Range: | 0.25~0.9MPa(35~130psi) | |||||||||

| Proof Pressure: | 1.5MPa(215psi) | |||||||||

| Temperature Range: | -20~70℃ | |||||||||

| Aacting Type: | Solenoid Control | |||||||||

| Exhaust Port Size: | PT1/4 | PT3/8 | PT1/2 | |||||||

| Power Connection: | Terminal、Gromme | |||||||||

| Standard Voltage: |

AC220V、110V、24V(50\60Hz)、DC12V、24V |

|||||||||

|

Voltage Rang: |

-15%~+10% |

|||||||||

| Insulation: |

Class B |

|||||||||

| Power Consumption: | AC:3.5VA:DC:2.5W | |||||||||

| Option Pressure Gauge: | F: Square Pressure Gauge; C:Circular Pressure Gauge | |||||||||

| Suitable F.R.L Type: | GC200-06 | GC200-08 | GC300-08 | GC300-10 | GC300-15 | GC400-10 |

GC400-15 |

|||

①PT thread, NPT thread and G thread are available.

1.Check whether the components have been damaged during transportation before installing and using.

2.Pay attention to whether the flow direction of air (notice “→” direction) and thread type are correct.

3.Please notice whether installation condition accords with technical requirements (such as “working pressure” and “applied temperature range”);

4.Avoid usage in an environment that exposes the filter and lubricator bowl through contact with Chlorine, solvent, aromatic essence, acid and alkali to avoid damage to the Filter and Lubricator bowl.

5.Regularly clean or change filter core. Lubricators and regulators shall be in descending order.

6.Keep the dust away. The dust cover shall be installed in intake and outlet when the device is dismantled and stored.

| GV20006C1A | GV20006F2FT | GV20008NAI | GV30008C1A | GV30010JNBIG | GV30015NAIT |

| GV20006C1AI | GV20006F2FIT | GV20008NAIG | GV30008C1AI | GV30010JNBIT | GV30015C1B |

| GV20006C2AT | GV20006F3FG | GV20008NAIT | GV30008C2AT | GV30010NB | GV30015C1BI |

| GV20006C2AIT | GV20006F3FIG | GV20008C1B | GV30008C2AIT | GV30010NBG | GV30015C2BT |

| GV20006C3AG | GV20006JC1F | GV20008C1BI | GV30008C3AG | GV30010NBT | GV30015C2BIT |

| GV20006C3AIG | GV20006JC1FI | GV20008C2BT | GV30008C3AIG | GV30010NBI | GV30015C3BG |

| GV20006F1AI | GV20006JC2FT | GV20008C2BIT | GV30008F1AI | GV30010NBIG | GV30015C3BIG |

| GV20006F2AT | GV20006JC2FIT | GV20008C3BG | GV30008F2AT | GV30010NBIT | GV30015F1BI |

| GV20006F2AIT | GV20006JC3FG | GV20008C3BIG | GV30008F2AIT | GV30010C1C | GV30015F2BT |

| GV20006F3AG | GV20006JC3FIG | GV20008F1BI | GV30008F3AG | GV30010C1CI | GV30015F2BIT |

| GV20006F3AIG | GV20006JF1F | GV20008F2BT | GV30008F3AIG | GV30010C2CT | GV30015F3BG |

| GV20006JC1A | GV20006JF1FI | GV20008F2BIT | GV30008JC1A | GV30010C2CIT | GV30015F3BIG |

| GV20006JC1AI | GV20006JF2FT | GV20008F3BG | GV30008JC1AI | GV30010C3CG | GV30015JC1B |

| GV20006JC2AT | GV20006JF2FIT | GV20008F3BIG | GV30008JC2AT | GV30010C3CIG | GV30015JC1BI |

| GV20006JC2AIT | GV20006JF3FG | GV20008JC1B | GV30008JC2AIT | GV30010F1C | GV30015JC2BT |

| GV20006JC3AG | GV20006JF3FIG | GV20008JC1BI | GV30008JC3AG | GV30010F1CI | GV30015JC2BIT |

| GV20006JC3AIG | GV20006JNF | GV20008JC2BT | GV30008JC3AIG | GV30010F2CT | GV30015JC3BG |

| GV20006JF1A | GV20006JNFG | GV20008JC2BIT | GV30008JF1A | GV30010F2CIT | GV30015JC3BIG |

| GV20006JF1AI | GV20006JNFT | GV20008JC3BG | GV30008JF1AI | GV30010F3CG | GV30015JF1B |

| GV20006JF2AT | GV20006JNFI | GV20008JC3BIG | GV30008JF2AT | GV30010F3CIG | GV30015JF1BI |

| GV20006JF2AIT | GV20006JNFIG | GV20008JF1B | GV30008JF2AIT | GV30010JC1C | GV30015JF2BT |

| GV20006JF3AG | GV20006JNFIT | GV20008JF1BI | GV30008JF3AG | GV30010JC1CI | GV30015JF2BIT |

| GV20006JF3AIG | GV20006NF | GV20008JF2BT | GV30008JF3AIG | GV30010JC2CT | GV30015JF3BG |

| GV20006JNA | GV20006NFG | GV20008JF2BIT | GV30008JNA | GV30010JC2CIT | GV30015JF3BIG |

| GV20006JNAG | GV20006NFT | GV20008JF3BG | GV30008JNAG | GV30010JC3CG | GV30015JNB |

| GV20006JNAT | GV20006NFI | GV20008JF3BIG | GV30008JNAT | GV30010JC3CIG | GV30015JNBG |

| GV20006JNAI | GV20006NFIG | GV20008JNB | GV30008JNAI | GV30010JF1C | GV30015JNBT |

| GV20006JNAIG | GV20006NFIT | GV20008JNBG | GV30008JNAIG | GV30010JF1CI | GV30015JNBI |

| GV20006JNAIT | GV20008C1A | GV20008JNBT | GV30008JNAIT | GV30010JF2CT | GV30015JNBIG |

| GV20006NA | GV20008C1AI | GV20008JNBI | GV30008NA | GV30010JF2CIT | GV30015JNBIT |

| GV20006NAG | GV20008C2AT | GV20008JNBIG | GV30008NAG | GV30010JF3CG | GV30015NB |

| GV20006NAT | GV20008C2AIT | GV20008JNBIT | GV30008NAT | GV30010JF3CIG | GV30015NBG |

| GV20006NAI | GV20008C3AG | GV20008NB | GV30008NAI | GV30010JNC | GV30015NBT |

| GV20006NAIG | GV20008C3AIG | GV20008NBG | GV30008NAIG | GV30010JNCG | GV30015NBI |

| GV20006NAIT | GV20008F1AI | GV20008NBT | GV30008NAIT | GV30010JNCT | GV30015NBIG |

| GV20006C1B | GV20008F2AT | GV20008NBI | GV30008C1B | GV30010JNCI | GV30015NBIT |

| GV20006C1BI | GV20008F2AIT | GV20008NBIG | GV30008C1BI | GV30010JNCIG | GV30015C1C |

| GV20006C2BT | GV20008F3AG | GV20008NBIT | GV30008C2BT | GV30010JNCIT | GV30015C1CI |

| GV20006C2BIT | GV20008F3AIG | GV20008C1C | GV30008C2BIT | GV30010NC | GV30015C2CT |

| GV20006C3BG | GV20008JC1A | GV20008C1CI | GV30008C3BG | GV30010NCG | GV30015C2CIT |

| GV20006C3BIG | GV20008JC1AI | GV20008C2CT | GV30008C3BIG | GV30010NCT | GV30015C3CG |

| GV20006F1BI | GV20008JC2AT | GV20008C2CIT | GV30008F1BI | GV30010NCI | GV30015C3CIG |

| GV20006F2BT | GV20008JC2AIT | GV20008C3CG | GV30008F2BT | GV30010NCIG | GV30015F1C |

| GV20006F2BIT | GV20008JC3AG | GV20008C3CIG | GV30008F2BIT | GV30010NCIT | GV30015F1CI |

| GV20006F3BG | GV20008JC3AIG | GV20008F1C | GV30008F3BG | GV30010C1E | GV30015F2CT |

| GV20006F3BIG | GV20008JF1A | GV20008F1CI | GV30008F3BIG | GV30010C1EI | GV30015F2CIT |

| GV20006JC1B | GV20008JF1AI | GV20008F2CT | GV30008JC1B | GV30010C2ET | GV30015F3CG |

| GV20006JC1BI | GV20008JF2AT | GV20008F2CIT | GV30008JC1BI | GV30010C2EIT | GV30015F3CIG |

| GV20006JC2BT | GV20008JF2AIT | GV20008F3CG | GV30008JC2BT | GV30010C3EG | GV30015JC1C |

| GV20006JC2BIT | GV20008JF3AG | GV20008F3CIG | GV30008JC2BIT | GV30010C3EIG | GV30015JC1CI |

| GV20006JC3BG | GV20008JF3AIG | GV20008JC1C | GV30008JC3BG | GV30010F1E | GV30015JC2CT |

| GV20006JC3BIG | GV20008JNA | GV20008JC1CI | GV30008JC3BIG | GV30010F1EI | GV30015JC2CIT |

| GV20006JF1B | GV20008JNAG | GV20008JC2CT | GV30008JF1B | GV30010F2ET | GV30015JC3CG |

| GV20006JF1BI | GV20008JNAT | GV20008JC2CIT | GV30008JF1BI | GV30010F2EIT | GV30015JC3CIG |

| GV20006JF2BT | GV20008JNAI | GV20008JC3CG | GV30008JF2BT | GV30010F3EG | GV30015JF1C |

| GV20006JF2BIT | GV20008JNAIG | GV20008JC3CIG | GV30008JF2BIT | GV30010F3EIG | GV30015JF1CI |

| GV20006JF3BG | GV20008JNAIT | GV20008JF1C | GV30008JF3BG | GV30010JC1E | GV30015JF2CT |

| GV20006JF3BIG | GV20008NA | GV20008JF1CI | GV30008JF3BIG | GV30010JC1EI | GV30015JF2CIT |

| GV20006JNB | GV20008NAG | GV20008JF2CT | GV30008JNB | GV30010JC2ET | GV30015JF3CG |

| GV20006JNBG | GV20008NAT | GV20008JF2CIT | GV30008JNBG | GV30010JC2EIT | GV30015JF3CIG |

| GV20006JNBT | GV30008F2FT | GV20008JF3CG | GV30008JNBT | GV30010JC3EG | GV30015JNC |

| GV20006JNBI | GV30008F2FIT | GV20008JF3CIG | GV30008JNBI | GV30010JC3EIG | GV30015JNCG |

| GV20006JNBIG | GV30008F3FG | GV20008JNC | GV30008JNBIG | GV30010JF1E | GV30015JNCT |

| GV20006JNBIT | GV30008F3FIG | GV20008JNCG | GV30008JNBIT | GV30010JF1EI | GV30015JNCI |

| GV20006NB | GV30008JC1F | GV20008JNCT | GV30008NB | GV30010JF2ET | GV30015JNCIG |

| GV20006NBG | GV30008JC1FI | GV20008JNCI | GV30008NBG | GV30010JF2EIT | GV30015JNCIT |

| GV20006NBT | GV30008JC2FT | GV20008JNCIG | GV30008NBT | GV30010JF3EG | GV30015NC |

| GV20006NBI | GV30008JC2FIT | GV20008JNCIT | GV30008NBI | GV30010JF3EIG | GV30015NCG |

| GV20006NBIG | GV30008JC3FG | GV20008NC | GV30008NBIG | GV30010JNE | GV30015NCT |

| GV20006NBIT | GV30008JC3FIG | GV20008NCG | GV30008NBIT | GV30010JNEG | GV30015NCI |

| GV20006C1C | GV30008JF1F | GV20008NCT | GV30008C1C | GV30010JNET | GV30015NCIG |

| GV20006C1CI | GV30008JF1FI | GV20008NCI | GV30008C1CI | GV30010JNEI | GV30015NCIT |

| GV20006C2CT | GV30008JF2FT | GV20008NCIG | GV30008C2CT | GV30010JNEIG | GV30015C1E |

| GV20006C2CIT | GV30008JF2FIT | GV20008NCIT | GV30008C2CIT | GV30010JNEIT | GV30015C1EI |

| GV20006C3CG | GV30008JF3FG | GV20008C1E | GV30008C3CG | GV30010NE | GV30015C2ET |

| GV20006C3CIG | GV30008JF3FIG | GV20008C1EI | GV30008C3CIG | GV30010NEG | GV30015C2EIT |

| GV20006F1C | GV30008JNF | GV20008C2ET | GV30008F1C | GV30010NET | GV30015C3EG |

| GV20006F1CI | GV30008JNFG | GV20008C2EIT | GV30008F1CI | GV30010NEI | GV30015C3EIG |

| GV20006F2CT | GV30008JNFT | GV20008C3EG | GV30008F2CT | GV30010NEIG | GV30015F1E |

| GV20006F2CIT | GV30008JNFI | GV20008C3EIG | GV30008F2CIT | GV30010NEIT | GV30015F1EI |

| GV20006F3CG | GV30008JNFIG | GV20008F1E | GV30008F3CG | GV30010C1F | GV30015F2ET |

| GV20006F3CIG | GV30008JNFIT | GV20008F1EI | GV30008F3CIG | GV30010C1FI | GV30015F2EIT |

| GV20006JC1C | GV30008NF | GV20008F2ET | GV30008JC1C | GV30010C2FT | GV30015F3EG |

| GV20006JC1CI | GV30008NFG | GV20008F2EIT | GV30008JC1CI | GV30010C2FIT | GV30015F3EIG |

| GV20006JC2CT | GV30008NFT | GV20008F3EG | GV30008JC2CT | GV30010C3FG | GV30015JC1E |

| GV20006JC2CIT | GV30008NFI | GV20008F3EIG | GV30008JC2CIT | GV30010C3FIG | GV30015JC1EI |

| GV20006JC3CG | GV30008NFIG | GV20008JC1E | GV30008JC3CG | GV30010F1F | GV30015JC2ET |

| GV20006JC3CIG | GV30008NFIT | GV20008JC1EI | GV30008JC3CIG | GV30010F1FI | GV30015JC2EIT |

| GV20006JF1C | GV30010C1A | GV20008JC2ET | GV30008JF1C | GV30010F2FT | GV30015JC3EG |

| GV20006JF1CI | GV30010C1AI | GV20008JC2EIT | GV30008JF1CI | GV30010F2FIT | GV30015JC3EIG |

| GV20006JF2CT | GV30010C2AT | GV20008JF1EG | GV30008JF2CT | GV30010F3FG | GV30015JF1E |

| GV20006JF2CIT | GV30010C2AIT | GV20008JC3EIG | GV30008JF2CIT | GV30010F3FIG | GV30015JF1EI |

| GV20006JF3CG | GV30010C3AG | GV20008JF1E | GV30008JF3CG | GV30010JC1F | GV30015JF2ET |

| GV20006JF3CIG | GV30010C3AIG | GV20008JF1EI | GV30008JF3CIG | GV30010JC1FI | GV30015JF2EIT |

| GV20006JNC | GV30010F1AI | GV20008JF2ET | GV30008JNC | GV30010JC2FT | GV30015JF3EG |

| GV20006JNCG | GV30010F2AT | GV20008JF2EIT | GV30008JNCG | GV30010JC2FIT | GV30015JF3EIG |

| GV20006JNCT | GV30010F2AIT | GV20008JF3EG | GV30008JNCT | GV30010JC3FG | GV30015JNE |

| GV20006JNCI | GV30010F3AG | GV20008JF3EIG | GV30008JNCI | GV30010JC3FIG | GV30015JNEG |

| GV20006JNCIG | GV30010F3AIG | GV20008JNE | GV30008JNCIG | GV30010JF1F | GV30015JNET |

| GV20006JNCIT | GV30010JC1A | GV20008JNEG | GV30008JNCIT | GV30010JF1FI | GV30015JNEI |

| GV20006NC | GV30010JC1AI | GV20008JNET | GV30008NC | GV30010JF2FT | GV30015JNEIG |

| GV20006NCG | GV30010JC2AT | GV20008JNEI | GV30008NCG | GV30010JF2FIT | GV30015JNEIT |

| GV20006NCT | GV30010JC2AIT | GV20008JNEIG | GV30008NCT | GV30010JF3FG | GV30015NE |

| GV20006NCI | GV30010JC3AG | GV20008JNEIT | GV30008NCI | GV30010JF3FIG | GV30015NEG |

| GV20006NCIG | GV30010JC3AIG | GV20008NE | GV30008NCIG | GV30010JNF | GV30015NET |

| GV20006NCIT | GV30010JF1A | GV20008NEG | GV30008NCIT | GV30010JNFG | GV30015NEI |

| GV20006C1E | GV30010JF1AI | GV20008NET | GV30008C1E | GV30010JNFT | GV30015NEIG |

| GV20006C1EI | GV30010JF2AT | GV20008NEI | GV30008C1EI | GV30010JNFI | GV30015NEIT |

| GV20006C2ET | GV30010JF2AIT | GV20008NEIG | GV30008C2ET | GV30010JNFIG | GV30015C1F |

| GV20006C2EIT | GV30010JF3AG | GV20008NEIT | GV30008C2EIT | GV30010JNFIT | GV30015C1FI |

| GV20006C3EG | GV30010JF3AIG | GV20008C1F | GV30008C3EG | GV30010NF | GV30015C2FT |

| GV20006C3EIG | GV30010JNA | GV20008C1FI | GV30008C3EIG | GV30010NFG | GV30015C2FIT |

| GV20006F1E | GV30010JNAG | GV20008C2FT | GV30008F1E | GV30010NFT | GV30015C3FG |

| GV20006F1EI | GV30010JNAT | GV20008C2FIT | GV30008F1EI | GV30010NFI | GV30015C3FIG |

| GV20006F2ET | GV30010JNAI | GV20008C3FG | GV30008F2ET | GV30010NFIG | GV30015F1F |

| GV20006F2EIT | GV30010JNAIG | GV20008C3FIG | GV30008F2EIT | GV30010NFIT | GV30015F1FI |

| GV20006F3EG | GV30010JNAIT | GV20008F1F | GV30008F3EG | GV30015C1A | GV30015F2FT |

| GV20006F3EIG | GV30010NA | GV20008F1FI | GV30008F3EIG | GV30015C1AI | GV30015F2FIT |

| GV20006JC1E | GV30010NAG | GV20008F2FT | GV30008JC1E | GV30015C2AT | GV30015F3FG |

| GV20006JC1EI | GV30010NAT | GV20008F2FIT | GV30008JC1EI | GV30015C2AIT | GV30015F3FIG |

| GV20006JC2ET | GV30010NAI | GV20008F3FG | GV30008JC2ET | GV30015C3AG | GV30015JC1F |

| GV20006JC2EIT | GV30010NAIG | GV20008F3FIG | GV30008JC2EIT | GV30015C3AIG | GV30015JC1FI |

| GV20006JC3EG | GV30010NAIT | GV20008JC1F | GV30008JC3EG | GV30015F1AI | GV30015JC2FT |

| GV20006JC3EIG | GV30010C1B | GV20008JC1FI | GV30008JC3EIG | GV30015F2AT | GV30015JC2FIT |

| GV20006JF1E | GV30010C1BI | GV20008JC2FT | GV30008JF1E | GV30015F2AIT | GV30015JC3FG |

| GV20006JF1EI | GV30010C2BT | GV20008JC2FIT | GV30008JF1EI | GV30015F3AG | GV30015JC3FIG |

| GV20006JF2ET | GV30010C2BIT | GV20008JC3FG | GV30008JF2ET | GV30015F3AIG | GV30015JF1F |

| GV20006JF2EIT | GV30010C3BG | GV20008JC3FIG | GV30008JF2EIT | GV30015JC1A | GV30015JF1FI |

| GV20006JF3EG | GV30010C3BIG | GV20008JF1F | GV30008JF3EG | GV30015JC1AI | GV30015JF2FT |

| GV20006JF3EIG | GV30010F1BI | GV20008JF1FI | GV30008JF3EIG | GV30015JC2AT | GV30015JF2FIT |

| GV20006JNE | GV30010F2BT | GV20008JF2FT | GV30008JNE | GV30015JC2AIT | GV30015JF3FG |

| GV20006JNEG | GV30010F2BIT | GV20008JF2FIT | GV30008JNEG | GV30015JC3AG | GV30015JF3FIG |

| GV20006JNET | GV30010F3BG | GV20008JF3FG | GV30008JNET | GV30015JC3AIG | GV30015JNF |

| GV20006JNEI | GV30010F3BIG | GV20008JF3FIG | GV30008JNEI | GV30015JF1A | GV30015JNFG |

| GV20006JNEIG | GV30010JC1B | GV20008JNF | GV30008JNEIG | GV30015JF1AI | GV30015JNFT |

| GV20006JNEIT | GV30010JC1BI | GV20008JNFG | GV30008JNEIT | GV30015JF2AT | GV30015JNFI |

| GV20006NE | GV30010JC2BT | GV20008JNFT | GV30008NE | GV30015JF2AIT | GV30015JNFIG |

| GV20006NEG | GV30010JC2BIT | GV20008JNFI | GV30008NEG | GV30015JF3AG | GV30015JNFIT |

| GV20006NET | GV30010JC3BG | GV20008JNFIG | GV30008NET | GV30015JF3AIG | GV30015NF |

| GV20006NEI | GV30010JC3BIG | GV20008JNFIT | GV30008NEI | GV30015JNA | GV30015NFG |

| GV20006NEIG | GV30010JF1B | GV20008NF | GV30008NEIG | GV30015JNAG | GV30015NFT |

| GV20006NEIT | GV30010JF1BI | GV20008NFG | GV30008NEIT | GV30015JNAT | GV30015NFI |

| GV20006C1F | GV30010JF2BT | GV20008NFT | GV30008C1F | GV30015JNAI | GV30015NFIG |

| GV20006C1FI | GV30010JF2BIT | GV20008NFI | GV30008C1FI | GV30015JNAIG | GV30015NFIT |

| GV20006C2FT | GV30010JF3BG | GV20008NFIG | GV30008C2FT | GV30015JNAIT | GV30008F1A |

| GV20006C2FIT | GV30010JF3BIG | GV20008NFIT | GV30008C2FIT | GV30015NA | GV30008F1B |

| GV20006C3FG | GV30010JNB | GV20006F1A | GV30008C3FG | GV30015NAG | GV30010F1A |

| GV20006C3FIG | GV30010JNBG | GV20006F1B | GV30008C3FIG | GV30015NAT | GV30010F1B |

| GV20006F1F | GV30010JNBT | GV20008F1A | GV30008F1F | GV30015NAI | GV30015F1A |

| GV20006F1FI | GV30010JNBI | GV20008F1B | GV30008F1FI | GV30015NAIG | GV30015F1B |

| GV40010F1EI | GV40010JC1FI | GV40015JF1AI | GV40015JNBG | GV40015NC | GV40015NEIT |

| GV40010F2ET | GV40010JC2FT | GV40015JF2AT | GV40015JNBT | GV40015NCG | GV40015C1F |

| GV40010F2EIT | GV40010JC2FIT | GV40015JF2AIT | GV40015JNBI | GV40015NCT | GV40015C1FI |

| GV40010F3EG | GV40010JC3FG | GV40015JF3AG | GV40015JNBIG | GV40015NCI | GV40015C2FT |

| GV40010F3EIG | GV40010JC3FIG | GV40015JF3AIG | GV40015JNBIT | GV40015NCIG | GV40015C2FIT |

| GV40010JC1E | GV40010JF1F | GV40015JNA | GV40015NB | GV40015NCIT | GV40015C3FG |

| GV40010JC1EI | GV40010JF1FI | GV40015JNAG | GV40015NBG | GV40015C1E | GV40015C3FIG |

| GV40010JC2ET | GV40010JF2FT | GV40015JNAT | GV40015NBT | GV40015C1EI | GV40015F1F |

| GV40010JC2EIT | GV40010JF2FIT | GV40015JNAI | GV40015NBI | GV40015C2ET | GV40015F1FI |

| GV40010JC3EG | GV40010JF3FG | GV40015JNAIG | GV40015NBIG | GV40015C2EIT | GV40015F2FT |

| GV40010JC3EIG | GV40010JF3FIG | GV40015JNAIT | GV40015NBIT | GV40015C3EG | GV40015F2FIT |

| GV40010JF1E | GV40010JNF | GV40015NA | GV40015C1C | GV40015C3EIG | GV40015F3FG |

| GV40010JF1EI | GV40010JNFG | GV40015NAG | GV40015C1CI | GV40015F1E | GV40015F3FIG |

| GV40010JF2ET | GV40010JNFT | GV40015NAT | GV40015C2CT | GV40015F1EI | GV40015JC1F |

| GV40010JF2EIT | GV40010JNFI | GV40015NAI | GV40015C2CIT | GV40015F2ET | GV40015JC1FI |

| GV40010JF3EG | GV40010JNFIG | GV40015NAIG | GV40015C3CG | GV40015F2EIT | GV40015JC2FT |

| GV40010JF3EIG | GV40010JNFIT | GV40015NAIT | GV40015C3CIG | GV40015F3EG | GV40015JC2FIT |

| GV40010JNE | GV40010NF | GV40015C1B | GV40015F1C | GV40015F3EIG | GV40015JC3FG |

| GV40010JNEG | GV40010NFG | GV40015C1BI | GV40015F1CI | GV40015JC1E | GV40015JC3FIG |

| GV40010JNET | GV40010NFT | GV40015C2BT | GV40015F2CT | GV40015JC1EI | GV40015JF1F |

| GV40010JNEI | GV40010NFI | GV40015C2BIT | GV40015F2CIT | GV40015JC2ET | GV40015JF1FI |

| GV40010JNEIG | GV40010NFIG | GV40015C3BG | GV40015F3CG | GV40015JC2EIT | GV40015JF2FT |

| GV40010JNEIT | GV40010NFIT | GV40015C3BIG | GV40015F3CIG | GV40015JC3EG | GV40015JF2FIT |

| GV40010NE | GV40015C1A | GV40015F1BI | GV40015JC1C | GV40015JC3EIG | GV40015JF3FG |

| GV40010NEG | GV40015C1AI | GV40015F2BT | GV40015JC1CI | GV40015JF1E | GV40015JF3FIG |

| GV40010NET | GV40015C2AT | GV40015F2BIT | GV40015JC2CT | GV40015JF1EI | GV40015JNF |

| GV40010NEI | GV40015C2AIT | GV40015F3BG | GV40015JC2CIT | GV40015JF2ET | GV40015JNFG |

| GV40010NEIG | GV40015C3AG | GV40015F3BIG | GV40015JC3CG | GV40015JF2EIT | GV40015JNFT |

| GV40010NEIT | GV40015C3AIG | GV40015JC1B | GV40015JC3CIG | GV40015JF3EG | GV40015JNFI |

| GV40010C1F | GV40015F1AI | GV40015JC1BI | GV40015JF1C | GV40015JF3EIG | GV40015JNFIG |

| GV40010C1FI | GV40015F2AT | GV40015JC2BT | GV40015JF1CI | GV40015JNE | GV40015JNFIT |

| GV40010C2FT | GV40015F2AIT | GV40015JC2BIT | GV40015JF2CT | GV40015JNEG | GV40015NF |

| GV40010C2FIT | GV40015F3AG | GV40015JC3BG | GV40015JF2CIT | GV40015JNET | GV40015NFG |

| GV40010C3FG | GV40015F3AIG | GV40015JC3BIG | GV40015JF3CG | GV40015JNEI | GV40015NFT |

| GV40010C3FIG | GV40015JC1A | GV40015JF1B | GV40015JF3CIG | GV40015JNEIG | GV40015NFI |

| GV40010F1F | GV40015JC1AI | GV40015JF1BI | GV40015JNC | GV40015JNEIT | GV40015NFIG |

| GV40010F1FI | GV40015JC2AT | GV40015JF2BT | GV40015JNCG | GV40015NE | GV40015NFIT |

| GV40010F2FT | GV40015JC2AIT | GV40015JF2BIT | GV40015JNCT | GV40015NEG | GV40010F1A |

| GV40010F2FIT | GV40015JC3AG | GV40015JF3BG | GV40015JNCI | GV40015NET | GV40010F1B |

| GV40010F3FG | GV40015JC3AIG | GV40015JF3BIG | GV40015JNCIG | GV40015NEI | GV40015F1A |

| GV40010F3FIG | GV40015JF1A | GV40015JNB | GV40015JNCIT | GV40015NEIG | GV40015F1B |

| GV40010JC1F |