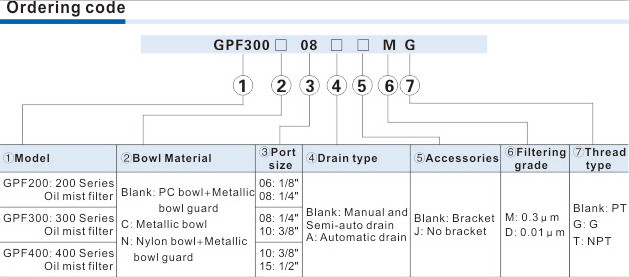

Product Name:GPF Series Air Control Preparation Unit Product Model:GPF20006 GPF20008 GPF30008 GPF30010 GPF40010 GPF40015 Filtering Grade:0.3μm or 0.01μm Brand:AiRTAC Fluid: Air Max Supply Pressure:1.0MPa(145psi) Proof Pressure: 1.5MPa(215psi)

|

Model: |

GPF20006 | GPF20008 | GPF30008 | GPF30010 | GPF40010 | GPF40015 | |

| Fluid: | Air | ||||||

| Port Size: | PT1/8 | PT1/4 | PT1/4 | PT3/8 | PT3/8 | PT1/2 | |

| Filtering Grade: | M | 0.3μm(Capture efficiency 99.9%) | |||||

| D | 0.01μm(Capture efficiency 99.9%) | ||||||

| Pressure Range: | 0.15~1.0MPa(20~145psi) | ||||||

| Proof Pressure: | 1.5MPa(215psi) | ||||||

| Temperature Range: | -5~70℃(Unfreeze) | ||||||

| Bowl Material: |

Polycarbonate, Nylon, Metal |

||||||

| Capacity of Drain Bowl: | 19CC |

54.5CC |

89CC | ||||

| Weight: | PC bowl: | 207g | 356g |

620g |

|||

| Metallic bowl: | 238g | 397g | 627g | ||||

①PT thread, NPT thread and G thread are available.

2. 0.3u m and 0.01 u m filtering grade are available.

3. Two drain types are available: manual and semi-auto drain, and automatic drain.

4. To meet the needs of different environment the bowl material has Poly Carbonate. nylon and metal can be selected.

5. Monomeric products can select the bracket for installation, others can be used with F.R. L Combination.

Installation & Usage:

1. Check whether the components have been damaged during transportation before installing and using.

2 Pay attention to whether the flow direction of air(notice- direction) and thread type are correct.

3. Please notice whether installation condition accords with technical requirements(such as working pressure and"applied temperature range)

4.Avoid usage in an environment that exposes the fiter and lubricator bow through contact with Chlorine, solvent, aromatic essence, acid and alkali to avoid damage to the Filter and Lubricator bowl.

5. Regularly clean or change filter core Lubric ators and regulators shall be in descending.

6. Keep the dust away The dust cover shall be installed in intake and outlet when the device is dismantled and stored.

| GPF20006M | GPF20008M | GPF30008M | GPF30010M | GPF40010M | GPF40015M |

| GPF20006MG | GPF20008MG | GPF30008MG | GPF30010MG | GPF40010MG | GPF40015MG |

| GPF20006MT | GPF20008MT | GPF30008MT | GPF30010MT | GPF40010MT | GPF40015MT |

| GPF20006D | GPF20008D | GPF30008D | GPF30010D | GPF40010D | GPF40015D |

| GPF20006DG | GPF20008DG | GPF30008DG | GPF30010DG | GPF40010DG | GPF40015DG |

| GPF20006DT | GPF20008DT | GPF30008DT | GPF30010DT | GPF40010DT | GPF40015DT |

| GPF20006JM | GPF20008JM | GPF30008JM | GPF30010JM | GPF40010JM | GPF40015JM |

| GPF20006JMG | GPF20008JMG | GPF30008JMG | GPF30010JMG | GPF40010JMG | GPF40015JMG |

| GPF20006JMT | GPF20008JMT | GPF30008JMT | GPF30010JMT | GPF40010JMT | GPF40015JMT |

| GPF20006JD | GPF20008JD | GPF30008JD | GPF30010JD | GPF40010JD | GPF40015JD |

| GPF20006JDG | GPF20008JDG | GPF30008JDG | GPF30010JDG | GPF40010JDG | GPF40015JDG |

| GPF20006JDT | GPF20008JDT | GPF30008JDT | GPF30010JDT | GPF40010JDT | GPF40015JDT |

| GPF20006AM | GPF20008AM | GPF30008AM | GPF30010AM | GPF40010AM | GPF40015AM |

| GPF20006AMG | GPF20008AMG | GPF30008AMG | GPF30010AMG | GPF40010AMG | GPF40015AMG |

| GPF20006AMT | GPF20008AMT | GPF30008AMT | GPF30010AMT | GPF40010AMT | GPF40015AMT |

| GPF20006AD | GPF20008AD | GPF30008AD | GPF30010AD | GPF40010AD | GPF40015AD |

| GPF20006ADG | GPF20008ADG | GPF30008ADG | GPF30010ADG | GPF40010ADG | GPF40015ADG |

| GPF20006ADT | GPF20008ADT | GPF30008ADT | GPF30010ADT | GPF40010ADT | GPF40015ADT |

| GPF20006AJM | GPF20008AJM | GPF30008AJM | GPF30010AJM | GPF40010AJM | GPF40015AJM |

| GPF20006AJMG | GPF20008AJMG | GPF30008AJMG | GPF30010AJMG | GPF40010AJMG | GPF40015AJMG |

| GPF20006AJMT | GPF20008AJMT | GPF30008AJMT | GPF30010AJMT | GPF40010AJMT | GPF40015AJMT |

| GPF20006AJD | GPF20008AJD | GPF30008AJD | GPF30010AJD | GPF40010AJD | GPF40015AJD |

| GPF20006AJDG | GPF20008AJDG | GPF30008AJDG | GPF30010AJDG | GPF40010AJDG | GPF40015AJDG |

| GPF20006AJDT | GPF20008AJDT | GPF30008AJDT | GPF30010AJDT | GPF40010AJDT | GPF40015AJDT |

| GPF200C06M | GPF200C08M | GPF300C08M | GPF300C10M | GPF400C10M | GPF400C15M |

| GPF200C06MG | GPF200C08MG | GPF300C08MG | GPF300C10MG | GPF400C10MG | GPF400C15MG |

| GPF200C06MT | GPF200C08MT | GPF300C08MT | GPF300C10MT | GPF400C10MT | GPF400C15MT |

| GPF200C06D | GPF200C08D | GPF300C08D | GPF300C10D | GPF400C10D | GPF400C15D |

| GPF200C06DG | GPF200C08DG | GPF300C08DG | GPF300C10DG | GPF400C10DG | GPF400C15DG |

| GPF200C06DT | GPF200C08DT | GPF300C08DT | GPF300C10DT | GPF400C10DT | GPF400C15DT |

| GPF200C06JM | GPF200C08JM | GPF300C08JM | GPF300C10JM | GPF400C10JM | GPF400C15JM |

| GPF200C06JMG | GPF200C08JMG | GPF300C08JMG | GPF300C10JMG | GPF400C10JMG | GPF400C15JMG |

| GPF200C06JMT | GPF200C08JMT | GPF300C08JMT | GPF300C10JMT | GPF400C10JMT | GPF400C15JMT |

| GPF200C06JD | GPF200C08JD | GPF300C08JD | GPF300C10JD | GPF400C10JD | GPF400C15JD |

| GPF200C06JDG | GPF200C08JDG | GPF300C08JDG | GPF300C10JDG | GPF400C10JDG | GPF400C15JDG |

| GPF200C06JDT | GPF200C08JDT | GPF300C08JDT | GPF300C10JDT | GPF400C10JDT | GPF400C15JDT |

| GPF200C06AM | GPF200C08AM | GPF300C08AM | GPF300C10AM | GPF400C10AM | GPF400C15AM |

| GPF200C06AMG | GPF200C08AMG | GPF300C08AMG | GPF300C10AMG | GPF400C10AMG | GPF400C15AMG |

| GPF200C06AMT | GPF200C08AMT | GPF300C08AMT | GPF300C10AMT | GPF400C10AMT | GPF400C15AMT |

| GPF200C06AD | GPF200C08AD | GPF300C08AD | GPF300C10AD | GPF400C10AD | GPF400C15AD |

| GPF200C06ADG | GPF200C08ADG | GPF300C08ADG | GPF300C10ADG | GPF400C10ADG | GPF400C15ADG |

| GPF200C06ADT | GPF200C08ADT | GPF300C08ADT | GPF300C10ADT | GPF400C10ADT | GPF400C15ADT |

| GPF200C06AJM | GPF200C08AJM | GPF300C08AJM | GPF300C10AJM | GPF400C10AJM | GPF400C15AJM |

| GPF200C06AJMG | GPF200C08AJMG | GPF300C08AJMG | GPF300C10AJMG | GPF400C10AJMG | GPF400C15AJMG |

| GPF200C06AJMT | GPF200C08AJMT | GPF300C08AJMT | GPF300C10AJMT | GPF400C10AJMT | GPF400C15AJMT |

| GPF200C06AJD | GPF200C08AJD | GPF300C08AJD | GPF300C10AJD | GPF400C10AJD | GPF400C15AJD |

| GPF200C06AJDG | GPF200C08AJDG | GPF300C08AJDG | GPF300C10AJDG | GPF400C10AJDG | GPF400C15AJDG |

| GPF200C06AJDT | GPF200C08AJDT | GPF300C08AJDT | GPF300C10AJDT | GPF400C10AJDT | GPF400C15AJDT |

| GPF200N06M | GPF200N08M | GPF300N08M | GPF300N10M | GPF400N10M | GPF400N15M |

| GPF200N06MG | GPF200N08MG | GPF300N08MG | GPF300N10MG | GPF400N10MG | GPF400N15MG |

| GPF200N06MT | GPF200N08MT | GPF300N08MT | GPF300N10MT | GPF400N10MT | GPF400N15MT |

| GPF200N06D | GPF200N08D | GPF300N08D | GPF300N10D | GPF400N10D | GPF400N15D |

| GPF200N06DG | GPF200N08DG | GPF300N08DG | GPF300N10DG | GPF400N10DG | GPF400N15DG |

| GPF200N06DT | GPF200N08DT | GPF300N08DT | GPF300N10DT | GPF400N10DT | GPF400N15DT |

| GPF200N06JM | GPF200N08JM | GPF300N08JM | GPF300N10JM | GPF400N10JM | GPF400N15JM |

| GPF200N06JMG | GPF200N08JMG | GPF300N08JMG | GPF300N10JMG | GPF400N10JMG | GPF400N15JMG |

| GPF200N06JMT | GPF200N08JMT | GPF300N08JMT | GPF300N10JMT | GPF400N10JMT | GPF400N15JMT |

| GPF200N06JD | GPF200N08JD | GPF300N08JD | GPF300N10JD | GPF400N10JD | GPF400N15JD |

| GPF200N06JDG | GPF200N08JDG | GPF300N08JDG | GPF300N10JDG | GPF400N10JDG | GPF400N15JDG |

| GPF200N06JDT | GPF200N08JDT | GPF300N08JDT | GPF300N10JDT | GPF400N10JDT | GPF400N15JDT |

| GPF200N06AM | GPF200N08AM | GPF300N08AM | GPF300N10AM | GPF400N10AM | GPF400N15AM |

| GPF200N06AMG | GPF200N08AMG | GPF300N08AMG | GPF300N10AMG | GPF400N10AMG | GPF400N15AMG |

| GPF200N06AMT | GPF200N08AMT | GPF300N08AMT | GPF300N10AMT | GPF400N10AMT | GPF400N15AMT |

| GPF200N06AD | GPF200N08AD | GPF300N08AD | GPF300N10AD | GPF400N10AD | GPF400N15AD |

| GPF200N06ADG | GPF200N08ADG | GPF300N08ADG | GPF300N10ADG | GPF400N10ADG | GPF400N15ADG |

| GPF200N06ADT | GPF200N08ADT | GPF300N08ADT | GPF300N10ADT | GPF400N10ADT | GPF400N15ADT |

| GPF200N06AJM | GPF200N08AJM | GPF300N08AJM | GPF300N10AJM | GPF400N10AJM | GPF400N15AJM |

| GPF200N06AJMG | GPF200N08AJMG | GPF300N08AJMG | GPF300N10AJMG | GPF400N10AJMG | GPF400N15AJMG |

| GPF200N06AJMT | GPF200N08AJMT | GPF300N08AJMT | GPF300N10AJMT | GPF400N10AJMT | GPF400N15AJMT |

| GPF200N06AJD | GPF200N08AJD | GPF300N08AJD | GPF300N10AJD | GPF400N10AJD | GPF400N15AJD |

| GPF200N06AJDG | GPF200N08AJDG | GPF300N08AJDG | GPF300N10AJDG | GPF400N10AJDG | GPF400N15AJDG |

| GPF200N06AJDT | GPF200N08AJDT | GPF300N08AJDT | GPF300N10AJDT | GPF400N10AJDT | GPF400N15AJDT |