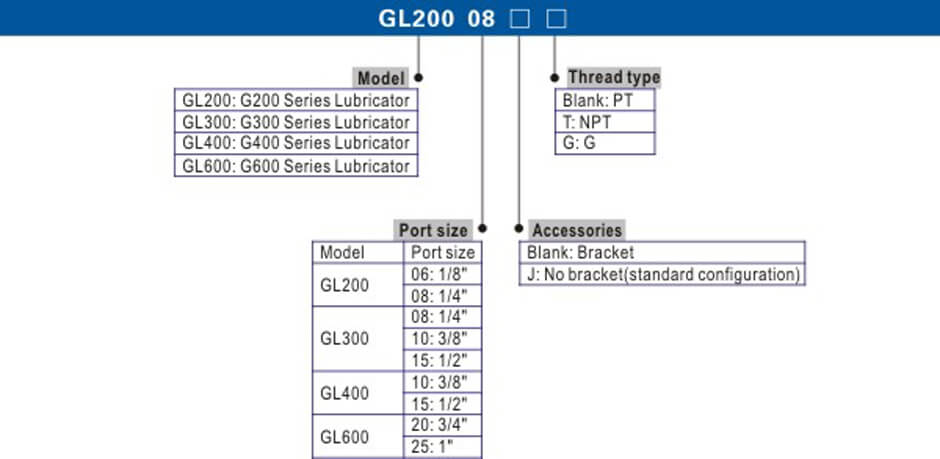

Product Name:GL Series Air Control Preparation Unit Product Model:GL200-06 GL200-08 GL300-08 GL300-10 GL300-15 GL400-10 GL400-15 GL600-20 GCL600-25 Filtering Grade:40μm or 5μm Brand:AiRTAC Fluid: Air Max Supply Pressure:1.0MPa(145psi) Proof Pressure: 1.5MPa(215psi)

|

Model: |

GL200-06 | GL200-08 | GL300-08 | GL300-10 | GL300-15 | GL400-10 | GL400-15 | GL600-20 | GL600-25 | |

| Fluid: | Air | |||||||||

| Port Size: | PT1/8 | PT1/4 | PT1/4 | PT3/8 | PT1/2 | PT3/8 | PT1/2 | PT3/4 | PT1 | |

| Pressure Range: | 0.05~0.9MPa(7~130psi) | |||||||||

| Proof Pressure: | 1.5MPa(215psi) | |||||||||

| Temperature Range: | -5~70℃ | |||||||||

| Recommended Lubricant: | ISO VG 30 or Equivalent | |||||||||

| Capacity of oil Bowl: | 25CC | 75CC | 160CC | 380CC | ||||||

| Weight: | 130g | 360g | 670g | 1300g | ||||||

①PT thread, NPT thread and G thread are available.

1.The structure of oil dripping adopts gap seal type, which makes the adjustment of oil supply more reliable.

2.Oil feed ring can only make one full turn.The quantity of oil supply basically takes on linear distribution. The quantity of oil supply can be generally calculated according to the position of graduation ring.

3.Special drip nozzle structure will produce negative pressure in oil dripping outlet and the mist flow is minimal.

4.Filling of oil while the lubricator is under pressure is made possible, and the oil bowl is large;

5.The bracket can be ed for installation.

Installation & Usage:

1.Check whether the components have been damaged during transportation before installing and using.

2.Pay attention to whether the flow direction of air (notice “→” direction) and thread type are correct.

3.Please notice whether installation condition accords with technical requirements (such as “working pressure” and “applied temperature range”);

4.Avoid usage in an environment that exposes the filter and lubricator bowl through contact with Chlorine, solvent, aromatic essence, acid and alkali to avoid damage to the Filter and Lubricator bowl.

5.Regularly clean or change filter core. Lubricators and regulators shall be in descending order.

6.Keep the dust away. The dust cover shall be installed in intake and outlet when the device is dismantled and stored.

|

GL30008G |

GL30008T | GL30008J |

| GL30008JT | GL30010G | GL30010T |

| GL30010JG | GL30010JT | GL30015G |

| GL30015J | GL30015JG | GL30015JT |

| GL30008JG | GL30010J | GL30015T |