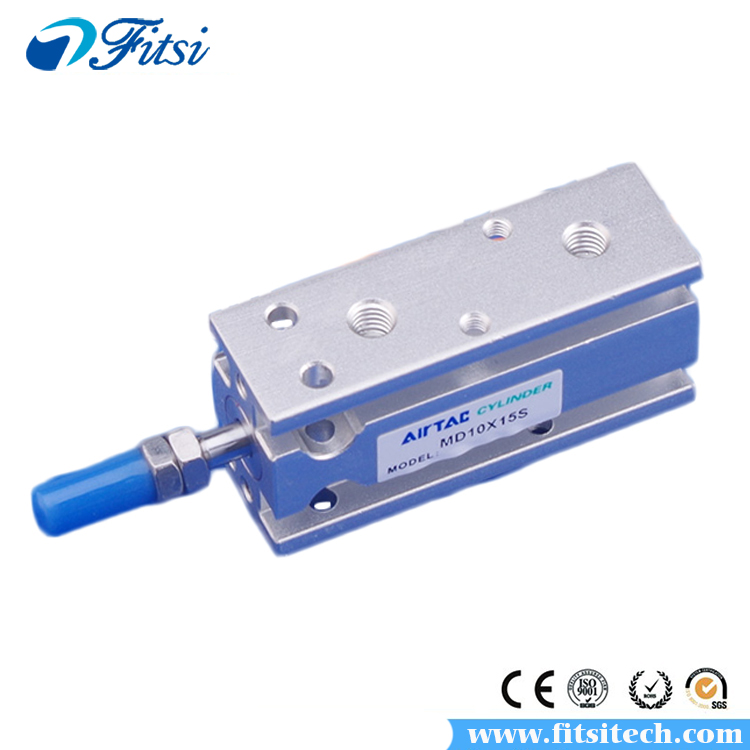

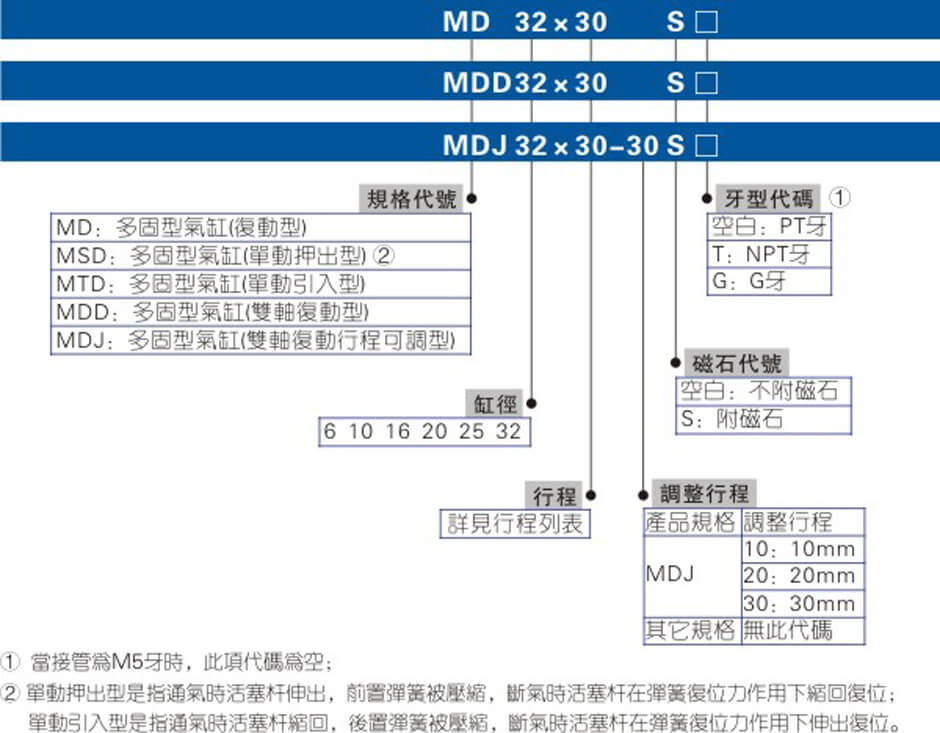

产品名称:MD、MDD、MDJ、MSD、MTD系列紧凑型气缸 产品型号:MD10X20 MD10X25 MD10X30 MD6X35 MD10X35 品牌: 亚德客(AirTAC) 工作介质: 空气 作动方式: 复动型,单动押出型、单动引入型

规格:

| 内径(mm): | 6 | 10 | 16 | 20 | 25 | 32 | |

|

作动型式: |

MD/MDD/MDJ | 复动型 | |||||

| MSD/MTD | 单动押出型、单动引入型 | ||||||

|

工作介质: |

空气(经40μm以上滤网过滤) | ||||||

| 使用压力范围: | 复动型: |

0.1~1.0MPa(15~145psi)(1.0~10.0bar) |

|||||

| 单动型: | 0.2~1.0MPa(28~145psi)(2.0~10.0bar) | ||||||

| 保证耐压力: | 1.5MPa(215psi) | ||||||

| 工作温度(℃): | -20~80 | ||||||

| 使用速度范围 (mm/s): | 复动型:30~500 单动型:50~500 | ||||||

| 行程公差范围: | (0~+1.0) | ||||||

| 缓冲型: | 防撞垫 | ||||||

| 接管口径: |

M5x0.8 |

PT1/8 | |||||

①接管牙型有NPT、G牙可供选择;.

行程:

|

内径(mm) |

标准行程(mm) | 最大行程(mm) | 容许行程(mm) | |

| 6 | 复动: | 5 10 15 20 25 30 35 | 35 | 40 |

| 单动: | 5 10 15 20 | 20 | - | |

|

10 |

复动: | 5 10 15 20 25 30 35 | 35 | 40 |

| 单动: | 5 10 15 20 | 20 | - | |

|

16 |

复动: | 5 10 15 20 25 30 40 50 |

50 |

70 |

| 单动: | 5 10 15 20 | 20 | - | |

| 20 |

复动: |

5 10 15 20 25 30 40 50 60 |

60 |

80 |

| 单动: | 5 10 15 20 | 20 | - | |

| 25 | 复动: | 5 10 15 20 25 30 40 50 60 | 60 | 80 |

| 单动: | 5 10 15 20 | 20 | - | |

|

32 |

复动: | 5 10 15 20 25 30 40 50 60 | 60 | 80 |

| 单动: | 5 10 15 20 | 20 | - | |

①在容许行程范围内,当行程>最大行程时,作非标处理,其他特殊行程请与本公司联系;

②最大行程范围内的非标行程以上一级标准行程改制而成,其外形尺寸为上一级标准行程气缸的外形尺寸。如行程为23的非标行程气缸是由标准行程为25的标准气缸改制而成,其外形尺寸与其相同。

1.Manufactured by our enterprise.

2.There are several ways to fix the cylinder and it is convenient to install and use.

3.Several cylinders can be assembled together to effectively save the installation space.

4.The guide precision of piston rod is high and no additional lubricant is needed.

5.Cylinders of various specifications are optional.

6.The seal material with high temperature resistance is adopted to guarantee the normal operation of cylinder at 150℃(Option).

Installation & Usage:

1. When load changes in the work, the cylinder with abundant output capacity shall be ed.

2.Relative cylinder with high temperature resistance or corrosion resistance shall be chosen under the condition of high temperature or corrosion.

3.Necessary protection measure shall be taken in the environment with higher humidity, much dust or water drops, oil dust and welding dregs.

4.Dirty substances in the pipe must be eliminated before cylinder is connected with pipeline to prevent the entrance of particles into the cylinder.

5.The medium used by cylinder shall be filtered to 40μm or below.

6.Anti-freezing measure shall be adopted under low temperature environment to prevent moisture freezing.

7.The cylinder shall be carried out test run without load before application. Prior to run, buffer shall be turned to the minimum and gradually released to avoid the damage on cylinder caused by excessive impact.

8.The cylinder shall avoid the influence of side load in operation to maintain the normal work of cylinder and extend the service life.

9. If the cylinder is dismantled and stored for a long time, please conduct anti-rust treatment to the surface. Anti-dust caps shall be added in air inlet and outlet ports.

| MD10X5 | MD10X25 | MD10X5S | MD10X25S |

| MD10X10 | MD10X30 | MD10X10S | MD10X30S |

| MD10X15 | MD10X35 | MD10X15S | MD10X35S |

| MD10X20 | MD10X40 | MD10X20S | MD10X40S |