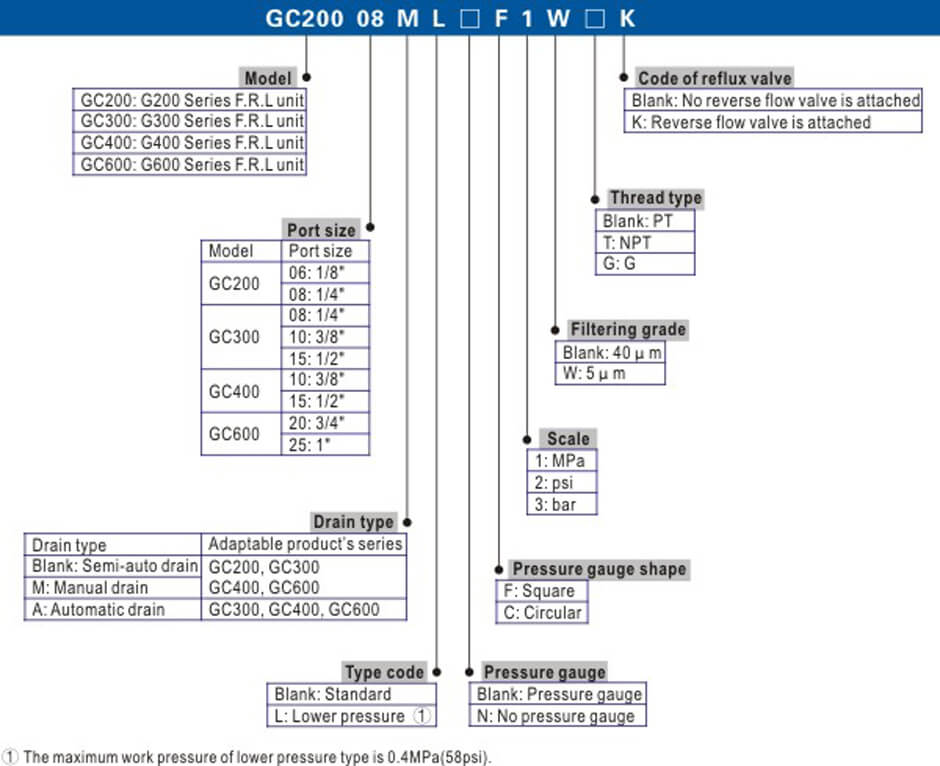

Product Name:GC Series Air Control Preparation Unit Product Model:GC200-06 GC200-08 GC300-08 GC300-10 GC300-15 GC400-10 GC400-15 GC600-20 GC600-25 Filtering Grade:40μm or 5μm Brand:AiRTAC Fluid: Air Max Supply Pressure:1.0MPa(145psi) Proof Pressure: 1.5MPa(215psi)

|

Model: |

GC200-06 | GC200-08 | GC300-08 | GC300-10 | GC300-15 | GC400-10 | GC400-15 | GC600-20 | GC600-25 | |

| Fluid: | Air | |||||||||

| Port Size: | PT1/8 | PT1/4 | PT1/4 | PT3/8 | PT1/2 | PT3/8 | PT1/2 | PT3/4 | PT1 | |

| Filtering Grade: | 40μm or 5μm | |||||||||

| Pressure Range: | Semi-auto and automatic drain:0.15~0.9MPa(20~130psi); Manual drain:0.05~0.9MPa(7~130psi) | |||||||||

| Max Pressure: | 1.0MPa(145psi) | |||||||||

| Proof Pressure: | 1.5MPa(215psi) | |||||||||

| Temperature Range: | -5~70℃ | |||||||||

| Capacity of Drain Bowl: | 10CC | 40CC | 80CC | 230CC | ||||||

| Capacity of Oil Bowl: | 25CC | 75CC | 160CC | 380CC | ||||||

| Recommended Lubricant: | ISO VG 30 or Equivalent | |||||||||

| Weight: | 580g | 1300g | 2360g | 5560g | ||||||

|

Constitube: |

Filter: | GF200-06 | GF200-08 | GF300-08 | GF300-10 | GF300-15 | GF400-10 | GF400-15 | GF600-20 | GF600-25 |

| Regulator: | GR200-06 | GR200-08 | GR300-08 | GR300-10 | GR300-15 | GR400-10 | GR400-15 | GR600-20 | GR600-25 | |

| Luricator | GL200-06 | GL200-08 | GL300-08 | GL300-10 | GL300-15 | GL400-10 | GL400-15 | GL600-20 | GL600-25 | |

①PT thread, NPT thread and G thread are available.

1.Oil dripping adopts gap seal structure, which makes the adjustment of oil supply more reliable.

2.Oil feed ring can only make one full turn. The quantity of oil supply, basically taking on linear distribution. The quantity of oil supply can be generally calculated according to the position of graduation ring.

3.Filling of oil while the lubricator is under pressure is made possible.

4.Special drip nozzle structure will produce negative pressure in oil dripping outlet and the mist flow is minimal.

5.Quick and reliable mounting clamps makes it convenient to install and use.

6.The performance of pressure adjustment is reliable with high precision.

7.The efficiency of eliminating moisture and solid grain is high.

8.Three drain types are available: manual drain, semiauto drain and automatic drain.

Installation & Usage:

1.Check whether the components have been damaged during transportation before installing and using.

2.Pay attention to whether the flow direction of air (notice “→” direction) and thread type are correct.

3.Please notice whether installation condition accords with technical requirements (such as “working pressure” and “applied temperature range”);

4.Avoid usage in an environment that exposes the filter and lubricator bowl through contact with Chlorine, solvent, aromatic essence, acid and alkali to avoid damage to the Filter and Lubricator bowl.

5.Regularly clean or change filter core. Lubricators and regulators shall be in descending order.

6.Keep the dust away. The dust cover shall be installed in intake and outlet when the device is dismantled and stored.

| GC20006C1K | GC200C06LC2T | GC300C08MLC2T | GC30010MLC3WGK | GC400C15MF3G | GC400C10LNK |

| GC20008C1WK | GC200C06LC2TK | GC300C08MLC2TK | GC30010MLF1 | GC400C15MF3GK | GC400C10LNT |

| GC20008C2T | GC200C06LC2WT | GC300C08MLC2WT | GC30010MLF1K | GC400C15MF3WG | GC400C10LNTK |

| GC20006C1WK | GC200C06LC2WTK | GC300C08MLC2WTK | GC30010MLF1W | GC400C15MF3WGK | GC400C10LNW |

| GC20008C2TK | GC200C06LC3G | GC300C08MLC3G | GC30010MLF1WK | GC400C15MC2T | GC400C10LNWG |

| GC20006C2T | GC200C06LC3GK | GC300C08MLC3GK | GC30010MLF2T | GC400C15MC2TK | GC400C10LNWGK |

| GC20008C2WT | GC200C06LC3WG | GC300C08MLC3WG | GC30010MLF2TK | GC400C15MC2WT | GC400C10LNWK |

| GC20006C2TK | GC200C06LC3WGK | GC300C08MLC3WGK | GC30010MLF2WT | GC400C15MC2WTK | GC400C10LNWT |

| GC20008C2WTK | GC200C06MF2T | GC300C08AF2T | GC30010MLF2WTK | GC400C15MC3G | GC400C10LNWTK |

| GC20006C2WT | GC200C06MF2TK | GC300C08AF2TK | GC30010MLF3G | GC400C15MC3GK | GC400C10MLN |

| GC20008C3G | GC200C06MF2WT | GC300C08AF2WT | GC30010MLF3GK | GC400C15MC3WG | GC400C10MLNG |

| GC20006C2WTK | GC200C06MF2WTK | GC300C08AF2WTK | GC30010MLF3WG | GC400C15MC3WGK | GC400C10MLNGK |

| GC20008C3GK | GC200C06MF3G | GC300C08AF3G | GC30010MLF3WGK | GC400C15MLF1 | GC400C10MLNK |

| GC20006C3G | GC200C06MF3GK | GC300C08AF3GK | GC30010MLN | GC400C15MLF1K | GC400C10MLNT |

| GC20008C3WG | GC200C06MF3WG | GC300C08AF3WG | GC30010MLNG | GC400C15MLF1W | GC400C10MLNTK |

| GC20006C3GK | GC200C06MF3WGK | GC300C08AF3WGK | GC30010MLNGK | GC400C15MLF1WK | GC400C10MLNW |

| GC20006C3WG | GC200C06MC2T | GC300C08AC2T | GC30010MLNK | GC400C15MLF2T | GC400C10MLNWG |

| GC20008C3WGK | GC200C06MC2TK | GC300C08AC2TK | GC30010MLNT | GC400C15MLF2TK | GC400C10MLNWGK |

| GC20008F1WK | GC200C06MC2WT | GC300C08AC2WT | GC30010MLNTK | GC400C15MLF2WT | GC400C10MLNWK |

| GC20006C3WGK | GC200C06MC2WTK | GC300C08AC2WTK | GC30010MLNW | GC400C15MLF2WTK | GC400C10MLNWT |

| GC20008F2T | GC200C06MC3G | GC300C08AC3G | GC30010MLNWG | GC400C15MLF3G | GC400C10MLNWTK |

| GC20006F1WK | GC200C06MC3GK | GC300C08AC3GK | GC30010MLNWGK | GC400C15MLF3GK | GC400C10MN |

| GC20008F2TK | GC200C06MC3WG | GC300C08AC3WG | GC30010MLNWK | GC400C15MLF3WG | GC400C10MNG |

| GC20006F2T | GC200C06MC3WGK | GC300C08AC3WGK | GC30010MLNWT | GC400C15MLF3WGK | GC400C10MNGK |

| GC20008F2WT | GC200C06MLF1 | GC300C08ALF1 | GC30010MLNWTK | GC400C15MLC1 | GC400C10MNK |

| GC20006F2TK | GC200C06MLF1K | GC300C08ALF1K | GC30010MN | GC400C15MLC1K | GC400C10MNT |

| GC20008F2WTK | GC200C06MLF1W | GC300C08ALF1W | GC30010MNG | GC400C15MLC1W | GC400C10MNTK |

| GC20006F2WT | GC200C06MLF1WK | GC300C08ALF1WK | GC30010MNGK | GC400C15MLC1WK | GC400C10MNW |

| GC20008F3G | GC200C06MLF2T | GC300C08ALF2T | GC30010MNK | GC400C15MLC2T | GC400C10MNWG |

| GC20006F2WTK | GC200C06MLF2TK | GC300C08ALF2TK | GC30010MNT | GC400C15MLC2TK | GC400C10MNWGK |

| GC20008F3GK | GC200C06MLF2WT | GC300C08ALF2WT | GC30010MNTK | GC400C15MLC2WT | GC400C10MNWK |

| GC20006F3G | GC200C06MLF2WTK | GC300C08ALF2WTK | GC30010MNW | GC400C15MLC2WTK | GC400C10MNWT |

| GC20006F3GK | GC200C06MLF3G | GC300C08ALF3G | GC30010MNWG | GC400C15MLC3G | GC400C10MNWTK |

| GC20008F3WG | GC200C06MLF3GK | GC300C08ALF3GK | GC30010MNWGK | GC400C15MLC3GK | GC400C10N |

| GC20008F3WGK | GC200C06MLF3WG | GC300C08ALF3WG | GC30010MNWK | GC400C15MLC3WG | GC400C10NG |

| GC20006F3WG | GC200C06MLF3WGK | GC300C08ALF3WGK | GC30010MNWT | GC400C15MLC3WGK | GC400C10NGK |

| GC20008LC1 | GC200C06MLC1 | GC300C08ALC1 | GC30010MNWTK | GC400C15AF2T | GC400C10NK |

| GC20006F3WGK | GC200C06MLC1K | GC300C08ALC1K | GC30010N | GC400C15AF2TK | GC400C10NT |

| GC20008LC1K | GC200C06MLC1W | GC300C08ALC1W | GC30010NG | GC400C15AF2WT | GC400C10NTK |

| GC20006LC1 | GC200C06MLC1WK | GC300C08ALC1WK | GC30010NGK | GC400C15AF2WTK | GC400C10NW |

| GC20008LC1W | GC200C06MLC2T | GC300C08ALC2T | GC30010NK | GC400C15AF3G | GC400C10NWG |

| GC20006LC1K | GC200C06MLC2TK | GC300C08ALC2TK | GC30010NT | GC400C15AF3GK | GC400C10NWGK |

| GC20008LC1WK | GC200C06MLC2WT | GC300C08ALC2WT | GC30010NTK | GC400C15AF3WG | GC400C10NWK |

| GC20006LC1W | GC200C06MLC2WTK | GC300C08ALC2WTK | GC30010NW | GC400C15AF3WGK | GC400C10NWT |

| GC20008LC2T | GC200C06MLC3G | GC300C08ALC3G | GC30010NWG | GC400C15AC2T | GC400C10NWTK |

| GC20006LC1WK | GC200C06MLC3GK | GC300C08ALC3GK | GC30010NWGK | GC400C15AC2TK | GC400C10AC1 |

| GC20008LC2TK | GC200C06MLC3WG | GC300C08ALC3WG | GC30010NWK | GC400C15AC2WT | GC400C10AC1K |

| GC20006LC2T | GC200C06MLC3WGK | GC300C08ALC3WGK | GC30010NWT | GC400C15AC2WTK | GC400C10AC1W |

| GC20006LC2TK | GC30010F1 | GC300C10F2T | GC30010NWTK | GC400C15AC3G | GC400C10AC1WK |

| GC20008LC2WT | GC300C08ALN | GC300C10F2TK | GC30010AC1 | GC400C15AC3GK | GC400C10AF1 |

| GC20008LC2WTK | GC300C15ALN | GC300C10F2WT | GC30010AC1K | GC400C15AC3WG | GC400C10AF1K |

| GC20006LC2WT | GC300C10ALN | GC300C10F2WTK | GC30010AC1W | GC400C15AC3WGK | GC400C10AF1W |

| GC20008LC3G | GC300C08ALNG | GC300C10F3G | GC30010AC1WK | GC400C15ALF1 | GC400C10AF1WK |

| GC20006LC2WTK | GC300C15ALNG | GC300C10F3GK | GC30010AF1 | GC400C15ALF1K | GC400C10C1 |

| GC20008LC3GK | GC300C10ALNG | GC300C10F3WG | GC30010AF1K | GC400C15ALF1W | GC400C10C1K |

| GC20006LC3G | GC300C08ALNGK | GC300C10F3WGK | GC30010AF1W | GC400C15ALF1WK | GC400C10C1W |

| GC20008LC3WG | GC300C15ALNGK | GC300C10C2T | GC30010AF1WK | GC400C15ALF2T | GC400C10C1WK |

| GC20006LC3GK | GC300C10ALNGK | GC300C10C2TK | GC30010C1 | GC400C15ALF2TK | GC400C10F1 |

| GC20008LC3WGK | GC300C08ALNK | GC300C10C2WT | GC30010C1K | GC400C15ALF2WT | GC400C10F1K |

| GC20006LC3WG | GC300C15ALNK | GC300C10C2WTK | GC30010C1W | GC400C15ALF2WTK | GC400C10F1W |

| GC20008LF1 | GC300C10ALNK | GC300C10C3G | GC30010C1WK | GC400C15ALF3G | GC400C10F1WK |

| GC20006LC3WGK | GC300C08ALNT | GC300C10C3GK | GC30010F1K | GC400C15ALF3GK | GC400C10MC1 |

| GC20008LF1K | GC300C15ALNT | GC300C10C3WG | GC30010F1W | GC400C15ALF3WG | GC400C10MC1K |

| GC20006LF1 | GC300C10ALNT | GC300C10C3WGK | GC30010MC1 | GC400C15ALF3WGK | GC400C10MC1W |

| GC20006LF1K | GC300C08ALNTK | GC300C10LF1 | GC30010MC1K | GC400C15ALC1 | GC400C10MC1WK |

| GC20008LF1W | GC300C15ALNTK | GC300C10LF1K | GC30010MC1W | GC400C15ALC1K | GC400C10MF1 |

| GC20008LF1WK | GC300C10ALNTK | GC300C10LF1W | GC30010MF1 | GC400C15ALC1W | GC400C10MF1K |

| GC20006LF1W | GC300C08ALNW | GC300C10LF1WK | GC30010MF1K | GC400C15ALC1WK | GC400C10MF1W |

| GC20008LF2T | GC300C15ALNW | GC300C10LF2T | GC30010MF1W | GC400C15ALC2T | GC400C10MF1WK |

| GC20006LF1WK | GC300C10ALNW | GC300C10LF2TK | GC30010MF1WK | GC400C15ALC2TK | GC400C15AC1 |

| GC20008LF2TK | GC300C10ALNWG | GC300C10LF2WT | GC30015AC1WK | GC400C15ALC2WT | GC400C15AC1K |

| GC20006LF2T | GC300C08ALNWG | GC300C10LF2WTK | GC30015AC2T | GC400C15ALC2WTK | GC400C15AC1W |

| GC20008LF2WT | GC300C15ALNWG | GC300C10LF3G | GC30015AC2TK | GC400C15ALC3G | GC400C15AC1WK |

| GC20006LF2TK | GC300C15ALNWGK | GC300C10LF3GK | GC30015AC2WT | GC400C15ALC3GK | GC400C15AF1 |

| GC20008LF2WTK | GC300C08ALNWGK | GC300C10LF3WG | GC30015AC2WTK | GC400C15ALC3WG | GC400C15AF1K |

| GC20006LF2WT | GC300C10ALNWGK | GC300C10LF3WGK | GC30015AC3G | GC400C15ALC3WGK | GC400C15AF1W |

| GC20008LF3G | GC300C15ALNWK | GC300C10LC1 | GC30015AC3GK | GC400C10MF2T | GC400C15AF1WK |

| GC20006LF2WTK | GC300C08ALNWK | GC300C10LC1K | GC30015AC3WG | GC400C10MF2TK | GC400C15C1 |

| GC20008LF3GK | GC300C10ALNWK | GC300C10LC1W | GC30015AC3WGK | GC400C10MF2WT | GC400C15C1K |

| GC20006LF3G | GC300C15ALNWT | GC300C10LC1WK | GC30015AF1K | GC400C10MF2WTK | GC400C15C1W |

| GC20006LF3GK | GC300C08ALNWT | GC300C10LC2T | GC30015AF1WK | GC400C10MF3G | GC400C15C1WK |

| GC20008LF3WG | GC300C10ALNWT | GC300C10LC2TK | GC30015AF2T | GC400C10MF3GK | GC400C15F1 |

| GC20008LF3WGK | GC300C15ALNWTK | GC300C10LC2WT | GC30015AF2TK | GC400C10MF3WG | GC400C15F1K |

| GC20006LF3WG | GC300C08ALNWTK | GC300C10LC2WTK | GC30015AF2WT | GC400C10MF3WGK | GC400C15F1W |

| GC20008LN | GC300C10ALNWTK | GC300C10LC3G | GC30015AF2WTK | GC400C10MC2T | GC400C15F1WK |

| GC20006LF3WGK | GC300C15AN | GC300C10LC3GK | GC30015AF3G | GC400C10MC2TK | GC400C15MC1 |

| GC20008LNG | GC300C08AN | GC300C10LC3WG | GC30015AF3GK | GC400C10MC2WT | GC400C15MC1K |

| GC20006LN | GC300C10AN | GC300C10LC3WGK | GC30015AF3WG | GC400C10MC2WTK | GC400C15MC1W |

| GC20008LNGK | GC300C15ANG | GC300C10MF2T | GC30015AF3WGK | GC400C10MC3G | GC400C15MC1WK |

| GC20006LNG | GC300C08ANG | GC300C10MF2TK | GC30015ALC1 | GC400C10MC3GK | GC400C15MF1 |

| GC20008LNK | GC300C10ANG | GC300C10MF2WT | GC30015ALC1K | GC400C10MC3WG | GC400C15MF1K |

| GC20006LNGK | GC300C15ANGK | GC300C10MF2WTK | GC30015ALC1W | GC400C10MC3WGK | GC400C15MF1W |

| GC20008LNT | GC300C08ANGK | GC300C10MF3G | GC30015ALC1WK | GC400C10MLF1 | GC400C15MF1WK |

| GC20006LNK | GC300C10ANGK | GC300C10MF3GK | GC30015ALC2T | GC400C10MLF1K | GC60025AC1 |

| GC20006LNT | GC300C10ANK | GC300C10MF3WG | GC30015ALC2TK | GC400C10MLF1W | GC60025AC1K |

| GC20008LNTK | GC300C15ANK | GC300C10MF3WGK | GC30015ALC2WT | GC400C10MLF1WK | GC60025AC1W |

| GC20006LNTK | GC300C08ANK | GC300C10MC2T | GC30015ALC2WTK | GC400C10MLF2T | GC60025AC1WK |

| GC20008LNW | GC300C15ANT | GC300C10MC2TK | GC30015ALC3G | GC400C10MLF2TK | GC60025AC2T |

| GC20008LNWG | GC300C08ANT | GC300C10MC2WT | GC30015ALC3GK | GC400C10MLF2WT | GC60025AC2TK |

| GC20006LNW | GC300C10ANT | GC300C10MC2WTK | GC30015ALC3WG | GC400C10MLF2WTK | GC60025AC2WT |

| GC20008LNWGK | GC300C15ANTK | GC300C10MC3G | GC30015ALC3WGK | GC400C10MLF3G | GC60025AC2WTK |

| GC20006LNWG | GC300C08ANTK | GC300C10MC3GK | GC30015ALF1 | GC400C10MLF3GK | GC60025AC3G |

| GC20008LNWK | GC300C10ANTK | GC300C10MC3WG | GC30015ALF1K | GC400C10MLF3WG | GC60025AC3GK |

| GC20006LNWGK | GC300C15ANW | GC300C10MC3WGK | GC30015ALF1W | GC400C10MLF3WGK | GC60025AC3WG |

| GC20008LNWT | GC300C08ANW | GC300C10MLF1 | GC30015ALF1WK | GC400C10MLC1 | GC60025AC3WGK |

| GC20006LNWK | GC300C10ANW | GC300C10MLF1K | GC30015ALF2T | GC400C10MLC1K | GC60025AF1 |

| GC20008LNWTK | GC300C15ANWG | GC300C10MLF1W | GC30015ALF2TK | GC400C10MLC1W | GC60025AF1K |

| GC20006LNWT | GC300C08ANWG | GC300C10MLF1WK | GC30015ALF2WT | GC400C10MLC1WK | GC60025AF1W |

| GC20008MC1WK | GC300C10ANWG | GC300C10MLF2T | GC30015ALF2WTK | GC400C10MLC2T | GC60025AF1WK |

| GC20006LNWTK | GC300C15ANWGK | GC300C10MLF2TK | GC30015ALF3G | GC400C10MLC2TK | GC60025AF2T |

| GC20006MC1K | GC300C08ANWGK | GC300C10MLF2WT | GC30015ALF3GK | GC400C10MLC2WT | GC60025AF2TK |

| GC20008MC2T | GC300C10ANWGK | GC300C10MLF2WTK | GC30015ALF3WG | GC400C10MLC2WTK | GC60025AF2WT |

| GC20006MC2T | GC300C15ANWK | GC300C10MLF3G | GC30015ALF3WGK | GC400C10MLC3G | GC60025AF2WTK |

| GC20008MC2TK | GC300C08ANWK | GC300C10MLF3GK | GC30015ALN | GC400C10MLC3GK | GC60025AF3G |

| GC20006MC2TK | GC300C10ANWK | GC300C10MLF3WG | GC30015ALNG | GC400C10MLC3WG | GC60025AF3GK |

| GC20008MC2WT | GC300C15ANWT | GC300C10MLF3WGK | GC30015ALNGK | GC400C10MLC3WGK | GC60025AF3WG |

| GC20008MC2WTK | GC300C08ANWT | GC300C10MLC1 | GC30015ALNK | GC400C10AF2T | GC60025AF3WGK |

| GC20006MC2WT | GC300C10ANWT | GC300C10MLC1K | GC30015ALNT | GC400C10AF2TK | GC60025ALC1 |

| GC20008MC3G | GC300C10ANWTK | GC300C10MLC1W | GC30015ALNTK | GC400C10AF2WT | GC60025ALC1K |

| GC20006MC2WTK | GC300C15ANWTK | GC300C10MLC1WK | GC30015ALNW | GC400C10AF2WTK | GC60025ALC1W |

| GC20008MC3GK | GC300C08ANWTK | GC300C10MLC2T | GC30015ALNWG | GC400C10AF3G | GC60025ALC1WK |

| GC20006MC3G | GC300C15LN | GC300C10MLC2TK | GC30015ALNWGK | GC400C10AF3GK | GC60025ALC2T |

| GC20008MC3WG | GC300C08LN | GC300C10MLC2WT | GC30015ALNWK | GC400C10AF3WG | GC60025ALC2TK |

| GC20006MC3GK | GC300C10LN | GC300C10MLC2WTK | GC30015ALNWT | GC400C10AF3WGK | GC60025ALC2WT |

| GC20008MC3WGK | GC300C15LNG | GC300C10MLC3G | GC30015ALNWTK | GC400C10AC2T | GC60025ALC2WTK |

| GC20006MC3WG | GC300C08LNG | GC300C10MLC3GK | GC30015AN | GC400C10AC2TK | GC60025ALC3G |

| GC20006MC3WGK | GC300C10LNG | GC300C10MLC3WG | GC30015ANG | GC400C10AC2WT | GC60025ALC3GK |

| GC20008MF2T | GC300C15LNGK | GC300C10MLC3WGK | GC30015ANGK | GC400C10AC2WTK | GC60025ALC3WG |

| GC20006MF1K | GC300C08LNGK | GC300C10AF2T | GC30015ANK | GC400C10AC3G | GC60025ALC3WGK |

| GC20008MF2TK | GC300C10LNGK | GC300C10AF2TK | GC30015ANT | GC400C10AC3GK | GC60025ALF1 |

| GC20006MF2T | GC300C15LNK | GC300C10AF2WT | GC30015ANTK | GC400C10AC3WG | GC60025ALF1K |

| GC20008MF2WT | GC300C08LNK | GC300C10AF2WTK | GC30015ANW | GC400C10AC3WGK | GC60025ALF1W |

| GC20008MF2WTK | GC300C10LNK | GC300C10AF3G | GC30015ANWG | GC400C10ALF1 | GC60025ALF1WK |

| GC20006MF2TK | GC300C15LNT | GC300C10AF3GK | GC30015ANWGK | GC400C10ALF1K | GC60025ALF2T |

| GC20008MF3G | GC300C08LNT | GC300C10AF3WG | GC30015ANWK | GC400C10ALF1W | GC60025ALF2TK |

| GC20006MF2WT | GC300C10LNT | GC300C10AF3WGK | GC30015ANWT | GC400C10ALF1WK | GC60025ALF2WT |

| GC20008MF3GK | GC300C08LNTK | GC300C10AC2T | GC30015ANWTK | GC400C10ALF2T | GC60025ALF2WTK |

| GC20006MF2WTK | GC300C15LNTK | GC300C10AC2TK | GC30015C1K | GC400C10ALF2TK | GC60025ALF3G |

| GC20008MF3WG | GC300C10LNTK | GC300C10AC2WT | GC30015C1WK | GC400C10ALF2WT | GC60025ALF3GK |

| GC20006MF3G | GC300C08LNW | GC300C10AC2WTK | GC30015C2T | GC400C10ALF2WTK | GC60025ALF3WG |

| GC20008MF3WGK | GC300C15LNW | GC300C10AC3G | GC30015C2TK | GC400C10ALF3G | GC60025ALF3WGK |

| GC20006MF3GK | GC300C10LNW | GC300C10AC3GK | GC30015C2WT | GC400C10ALF3GK | GC60025ALN |

| GC20006MF3WG | GC300C10LNWG | GC300C10AC3WG | GC30015C2WTK | GC400C10ALF3WG | GC60025ALNG |

| GC20008MLC1 | GC300C08LNWG | GC300C10AC3WGK | GC30015C3G | GC400C10ALF3WGK | GC60025ALNGK |

| GC20006MF3WGK | GC300C15LNWG | GC300C10ALF1 | GC30015C3GK | GC400C10ALC1 | GC60025ALNK |

| GC20008MLC1K | GC300C08LNWGK | GC300C10ALF1K | GC30015C3WG | GC400C10ALC1K | GC60025ALNT |

| GC20006MLC1 | GC300C15LNWGK | GC300C10ALF1W | GC30015C3WGK | GC400C10ALC1W | GC60025ALNTK |

| GC20008MLC1W | GC300C10LNWGK | GC300C10ALF1WK | GC30015F1WK | GC400C10ALC1WK | GC60025ALNW |

| GC20008MLC1WK | GC300C08LNWK | GC300C10ALF2T | GC30015F2T | GC400C10ALC2T | GC60025ALNWG |

| GC20006MLC1K | GC300C15LNWK | GC300C10ALF2TK | GC30015F2TK | GC400C10ALC2TK | GC60025ALNWGK |

| GC20008MLC2T | GC300C10LNWK | GC300C10ALF2WT | GC30015F2WT | GC400C10ALC2WT | GC60025ALNWK |

| GC20006MLC1W | GC300C08LNWT | GC300C10ALF2WTK | GC30015F2WTK | GC400C10ALC2WTK | GC60025ALNWT |

| GC20008MLC2TK | GC300C15LNWT | GC300C10ALF3G | GC30015F3G | GC400C10ALC3G | GC60025ALNWTK |

| GC20006MLC1WK | GC300C10LNWT | GC300C10ALF3GK | GC30015F3GK | GC400C10ALC3GK | GC60025AN |

| GC20008MLC2WT | GC300C08LNWTK | GC300C10ALF3WG | GC30015F3WG | GC400C10ALC3WG | GC60025ANG |

| GC20006MLC2T | GC300C15LNWTK | GC300C10ALF3WGK | GC30015F3WGK | GC400C10ALC3WGK | GC60025ANGK |

| GC20008MLC2WTK | GC300C10LNWTK | GC300C10ALC1 | GC30015LC1 | GC400C15ALN | GC60025ANK |

| GC20006MLC2TK | GC300C08MLN | GC300C10ALC1K | GC30015LC1K | GC400C15ALNG | GC60025ANT |

| GC20006MLC2WT | GC300C15MLN | GC300C10ALC1W | GC30015LC1W | GC400C15ALNGK | GC60025ANTK |

| GC20008MLC3G | GC300C10MLN | GC300C10ALC1WK | GC30015LC1WK | GC400C15ALNK | GC60025ANW |

| GC20006MLC2WTK | GC300C08MLNG | GC300C10ALC2T | GC30015LC2T | GC400C15ALNT | GC60025ANWG |

| GC20008MLC3GK | GC300C15MLNG | GC300C10ALC2TK | GC30015LC2TK | GC400C15ALNTK | GC60025ANWGK |

| GC20006MLC3G | GC300C10MLNG | GC300C10ALC2WT | GC30015LC2WT | GC400C15ALNW | GC60025ANWK |

| GC20008MLC3WG | GC300C08MLNGK | GC300C10ALC2WTK | GC30015LC2WTK | GC400C15ALNWG | GC60025ANWT |

| GC20008MLC3WGK | GC300C15MLNGK | GC300C10ALC3G | GC30015LC3G | GC400C15ALNWGK | GC60025ANWTK |

| GC20006MLC3GK | GC300C10MLNGK | GC300C10ALC3GK | GC30015LC3GK | GC400C15ALNWK | GC60025C1 |

| GC20008MLF1 | GC300C10MLNK | GC300C10ALC3WG | GC30015LC3WG | GC400C15ALNWT | GC60025C1K |

| GC20006MLC3WG | GC300C08MLNK | GC300C10ALC3WGK | GC30015LC3WGK | GC400C15ALNWTK | GC60025C1W |

| GC20008MLF1K | GC300C15MLNK | GC30008AC2T | GC30015LF1 | GC400C15AN | GC60025C1WK |

| GC20006MLC3WGK | GC300C08MLNT | GC30008AC2TK | GC30015LF1K | GC400C15ANG | GC60025C2T |

| GC20008MLF1W | GC300C15MLNT | GC30008AC2WT | GC30015LF1W | GC400C15ANGK | GC60025C2TK |

| GC20006MLF1 | GC300C10MLNT | GC30008AC2WTK | GC30015LF1WK | GC400C15ANK | GC60025C2WT |

| GC20008MLF1WK | GC300C08MLNTK | GC30008AC3G | GC30015LF2T | GC400C15ANT | GC60025C2WTK |

| GC20006MLF1K | GC300C15MLNTK | GC30008AC3GK | GC30015LF2TK | GC400C15ANTK | GC60025C3G |

| GC20006MLF1W | GC300C10MLNTK | GC30008AC3WG | GC30015LF2WT | GC400C15ANW | GC60025C3GK |

| GC20008MLF2T | GC300C08MLNW | GC30008AC3WGK | GC30015LF2WTK | GC400C15ANWG | GC60025C3WG |

| GC20006MLF1WK | GC300C15MLNW | GC30008AF1WK | GC30015LF3G | GC400C15ANWGK | GC60025C3WGK |

| GC20008MLF2TK | GC300C10MLNW | GC30008AF2T | GC30015LF3GK | GC400C15ANWK | GC60025F1K |

| GC20006MLF2T | GC300C15MLNWG | GC30008AF2TK | GC30015LF3WG | GC400C15ANWT | GC60025F1W |

| GC20008MLF2WT | GC300C08MLNWG | GC30008AF2WT | GC30015LF3WGK | GC400C15ANWTK | GC60025F1WK |

| GC20008MLF2WTK | GC300C10MLNWG | GC30008AF2WTK | GC30015LN | GC400C15LN | GC60025F2T |

| GC20006MLF2TK | GC300C15MLNWGK | GC30008AF3G | GC30015LNG | GC400C15LNG | GC60025F2TK |

| GC20008MLF3G | GC300C08MLNWGK | GC30008AF3GK | GC30015LNGK | GC400C15LNGK | GC60025F2WT |

| GC20006MLF2WT | GC300C10MLNWGK | GC30008AF3WG | GC30015LNK | GC400C15LNK | GC60025F2WTK |

| GC20008MLF3GK | GC300C15MLNWK | GC30008AF3WGK | GC30015LNT | GC400C15LNT | GC60025F3G |

| GC20006MLF2WTK | GC300C08MLNWK | GC30008ALC1 | GC30015LNTK | GC400C15LNTK | GC60025F3GK |

| GC20008MLF3WG | GC300C10MLNWK | GC30008ALC1K | GC30015LNW | GC400C15LNW | GC60025F3WG |

| GC20006MLF3G | GC300C15MLNWT | GC30008ALC1W | GC30015LNWG | GC400C15LNWG | GC60025F3WGK |

| GC20008MLF3WGK | GC300C08MLNWT | GC30008ALC1WK | GC30015LNWGK | GC400C15LNWGK | GC60025LC1 |

| GC20006MLF3GK | GC300C10MLNWT | GC30008ALC2T | GC30015LNWK | GC400C15LNWK | GC60025LC1K |

| GC20006MLF3WG | GC300C10MLNWTK | GC30008ALC2TK | GC30015LNWT | GC400C15LNWT | GC60025LC1W |

| GC20008MLN | GC300C15MLNWTK | GC30008ALC2WT | GC30015LNWTK | GC400C15LNWTK | GC60025LC1WK |

| GC20006MLF3WGK | GC300C08MLNWTK | GC30008ALC2WTK | GC30015MC1K | GC400C15MLN | GC60025LC2T |

| GC20008MLNG | GC300C15MN | GC30008ALC3G | GC30015MC1W | GC400C15MLNG | GC60025LC2TK |

| GC20006MLN | GC300C08MN | GC30008ALC3GK | GC30015MC1WK | GC400C15MLNGK | GC60025LC2WT |

| GC20008MLNGK | GC300C10MN | GC30008ALC3WG | GC30015MC2T | GC400C15MLNK | GC60025LC2WTK |

| GC20008MLNK | GC300C15MNG | GC30008ALC3WGK | GC30015MC2TK | GC400C15MLNT | GC60025LC3G |

| GC20006MLNG | GC300C08MNG | GC30008ALF1 | GC30015MC2WT | GC400C15MLNTK | GC60025LC3GK |

| GC20008MLNT | GC300C10MNG | GC30008ALF1K | GC30015MC2WTK | GC400C15MLNW | GC60025LC3WG |

| GC20006MLNGK | GC300C15MNGK | GC30008ALF1W | GC30015MC3G | GC400C15MLNWG | GC60025LC3WGK |

| GC20008MLNTK | GC300C08MNGK | GC30008ALF1WK | GC30015MC3GK | GC400C15MLNWGK | GC60025LF1 |

| GC20006MLNK | GC300C10MNGK | GC30008ALF2T | GC30015MC3WG | GC400C15MLNWK | GC60025LF1K |

| GC20008MLNW | GC300C15MNK | GC30008ALF2TK | GC30015MC3WGK | GC400C15MLNWT | GC60025LF1W |

| GC20006MLNT | GC300C08MNK | GC30008ALF2WT | GC30015MF2T | GC400C15MLNWTK | GC60025LF1WK |

| GC20008MLNWG | GC300C10MNK | GC30008ALF2WTK | GC30015MF2TK | GC400C15MN | GC60025LF2T |

| GC20006MLNTK | GC300C15MNT | GC30008ALF3G | GC30015MF2WT | GC400C15MNG | GC60025LF2TK |

| GC20006MLNW | GC300C08MNT | GC30008ALF3GK | GC30015MF2WTK | GC400C15MNGK | GC60025LF2WT |

| GC20008MLNWGK | GC300C10MNT | GC30008ALF3WG | GC30015MF3G | GC400C15MNK | GC60025LF2WTK |

| GC20006MLNWG | GC300C15MNTK | GC30008ALF3WGK | GC30015MF3GK | GC400C15MNT | GC60025LF3G |

| GC20008MLNWK | GC300C08MNTK | GC30008ALN | GC30015MF3WG | GC400C15MNTK | GC60025LF3GK |

| GC20006MLNWGK | GC300C10MNTK | GC30008ALNG | GC30015MF3WGK | GC400C15MNW | GC60025LF3WG |

| GC20008MLNWT | GC300C15MNW | GC30008ALNGK | GC30015MLC1 | GC400C15MNWG | GC60025LF3WGK |

| GC20008MLNWTK | GC300C08MNW | GC30008ALNK | GC30015MLC1K | GC400C15MNWGK | GC60025LN |

| GC20006MLNWK | GC300C10MNW | GC30008ALNT | GC30015MLC1W | GC400C15MNWK | GC60025LNG |

| GC20008MN | GC300C10MNWG | GC30008ALNTK | GC30015MLC1WK | GC400C15MNWT | GC60025LNGK |

| GC20006MLNWT | GC300C15MNWG | GC30008ALNW | GC30015MLC2T | GC400C15MNWTK | GC60025LNK |

| GC20008MNG | GC300C08MNWG | GC30008ALNWG | GC30015MLC2TK | GC400C15N | GC60025LNTK |

| GC20006MLNWTK | GC300C15MNWGK | GC30008ALNWGK | GC30015MLC2WT | GC400C15NG | GC60025LNW |

| GC20008MNGK | GC300C08MNWGK | GC30008ALNWK | GC30015MLC2WTK | GC400C15NGK | GC60025LNWG |

| GC20006MN | GC300C10MNWGK | GC30008ALNWT | GC30015MLC3G | GC400C15NK | GC60025LNWGK |

| GC20008MNK | GC300C15MNWK | GC30008ALNWTK | GC30015MLC3GK | GC400C15NT | GC60025LNWK |

| GC20006MNG | GC300C08MNWK | GC30008AN | GC30015MLC3WG | GC400C15NTK | GC60025LNWT |

| GC20006MNGK | GC300C10MNWK | GC30008ANG | GC30015MLC3WGK | GC400C15NW | GC60025LNWTK |

| GC20008MNT | GC300C15MNWT | GC30008ANGK | GC30015MLF1 | GC400C15NWG | GC60025MC1K |

| GC20006MNK | GC300C08MNWT | GC30008ANK | GC30015MLF1K | GC400C15NWGK | GC60025MC1WK |

| GC20008MNTK | GC300C10MNWT | GC30008ANT | GC30015MLF1W | GC400C15NWK | GC60025MC2T |

| GC20006MNT | GC300C15MNWTK | GC30008ANTK | GC30015MLF1WK | GC400C15NWT | GC60025MC2TK |

| GC20008MNW | GC300C08MNWTK | GC30008ANW | GC30015MLF2T | GC400C15NWTK | GC60025MC2WT |

| GC20008MNWG | GC300C10MNWTK | GC30008ANWG | GC30015MLF2TK | GC40010AC1WK | GC60025MC2WTK |

| GC20006MNTK | GC300C15N | GC30008ANWGK | GC30015MLF2WT | GC40010AC2T | GC60025MC3G |

| GC20008MNWGK | GC300C08N | GC30008ANWK | GC30015MLF2WTK | GC40010AC2TK | GC60025MC3GK |

| GC20006MNW | GC300C10N | GC30008ANWT | GC30015MLF3G | GC40010AC2WT | GC60025MC3WG |

| GC20008MNWK | GC300C15NG | GC30008ANWTK | GC30015MLF3GK | GC40010AC2WTK | GC60025MC3WGK |

| GC20006MNWG | GC300C08NG | GC30008C1WK | GC30015MLF3WG | GC40010AC3G | GC60025MF1 |

| GC20008MNWT | GC300C10NG | GC30008C2T | GC30015MLF3WGK | GC40010AC3GK | GC60025MF1K |

| GC20006MNWGK | GC300C15NGK | GC30008C2TK | GC30015MLN | GC40010AC3WG | GC60025MF1W |

| GC20006MNWK | GC300C08NGK | GC30008C2WT | GC30015MLNG | GC40010AC3WGK | GC60025MF1WK |

| GC20008MNWTK | GC300C10NGK | GC30008C2WTK | GC30015MLNGK | GC40010AF1W | GC60025MF2T |

| GC20006MNWT | GC300C10NK | GC30008C3G | GC30015MLNK | GC40010AF1WK | GC60025MF2TK |

| GC20008N | GC300C15NK | GC30008C3GK | GC30015MLNT | GC40010AF2T | GC60025MF2WT |

| GC20006MNWTK | GC300C08NK | GC30008C3WG | GC30015MLNTK | GC40010AF2TK | GC60025MF2WTK |

| GC20008NG | GC300C08NT | GC30008C3WGK | GC30015MLNW | GC40010AF2WT | GC60025MF3G |

| GC20006N | GC300C10NT | GC30008F2T | GC30015MLNWG | GC40010AF2WTK | GC60025MF3GK |

| GC20008NGK | GC300C15NT | GC30008F2TK | GC30015MLNWGK | GC40010AF3G | GC60025MF3WG |

| GC20006NG | GC300C08NTK | GC30008F2WT | GC30015MLNWK | GC40010AF3GK | GC60025MF3WGK |

| GC20008NK | GC300C10NTK | GC30008F2WTK | GC30015MLNWT | GC40010AF3WG | GC60025MLC1 |

| GC20006NGK | GC300C15NTK | GC30008F3G | GC30015MLNWTK | GC40010AF3WGK | GC60025MLC1K |

| GC20008NT | GC300C08NW | GC30008F3GK | GC30015MN | GC40010ALC1 | GC60025MLC1W |

| GC20006NK | GC300C10NW | GC30008F3WG | GC30015MNG | GC40010ALC1K | GC60025MLC1WK |

| GC20008NTK | GC300C15NW | GC30008F3WGK | GC30015MNGK | GC40010ALC1W | GC60025MLC2T |

| GC20008NW | GC300C15NWG | GC30008LC1 | GC30015MNK | GC40010ALC1WK | GC60025MLC2TK |

| GC20006NT | GC300C08NWG | GC30008LC1K | GC30015MNT | GC40010ALC2T | GC60025MLC2WT |

| GC20006NTK | GC300C10NWG | GC30008LC1W | GC30015MNTK | GC40010ALC2TK | GC60025MLC2WTK |

| GC20008NWG | GC300C15NWGK | GC30008LC1WK | GC30015MNW | GC40010ALC2WT | GC60025MLC3G |

| GC20006NW | GC300C10NWGK | GC30008LC2T | GC30015MNWG | GC40010ALC2WTK | GC60025MLC3GK |

| GC20008NWGK | GC300C08NWGK | GC30008LC2TK | GC30015MNWGK | GC40010ALC3G | GC60025MLC3WG |

| GC20006NWG | GC300C15NWK | GC30008LC2WT | GC30015MNWK | GC40010ALC3GK | GC60025MLC3WGK |

| GC20008NWK | GC300C10NWK | GC30008LC2WTK | GC30015MNWT | GC40010ALC3WG | GC60025MLF1 |

| GC20006NWGK | GC300C08NWK | GC30008LC3G | GC30015MNWTK | GC40010ALC3WGK | GC60025MLF1K |

| GC20008NWT | GC300C15NWT | GC30008LC3GK | GC30015N | GC40010ALF1 | GC60025MLF1W |

| GC20006NWK | GC300C10NWT | GC30008LC3WG | GC30015NG | GC40010ALF1K | GC60025MLF1WK |

| GC20008NWTK | GC300C08NWT | GC30008LC3WGK | GC30015NGK | GC40010ALF1W | GC60025MLF2T |

| GC20008C1 | GC300C08NWTK | GC30008LF1 | GC30015NK | GC40010ALF1WK | GC60025MLF2TK |

| GC20006NWT | GC300C15NWTK | GC30008LF1K | GC30015NT | GC40010ALF2T | GC60025MLF2WT |

| GC20008C1K | GC300C10NWTK | GC30008LF1W | GC30015NTK | GC40010ALF2TK | GC60025MLF2WTK |

| GC20006NWTK | GC300C08AC1 | GC30008LF1WK | GC30015NW | GC40010ALF2WT | GC60025MLF3G |

| GC20008C1W | GC300C15AC1 | GC30008LF2T | GC30015NWG | GC40010ALF2WTK | GC60025MLF3GK |

| GC20008F1 | GC300C10AC1 | GC30008LF2TK | GC30015NWGK | GC40010ALF3G | GC60025MLF3WG |

| GC20008F1K | GC300C08AC1K | GC30008LF2WT | GC30015NWK | GC40010ALF3GK | GC60025MLF3WGK |

| GC20008F1W | GC300C15AC1K | GC30008LF2WTK | GC30015NWT | GC40010ALF3WG | GC60025MLN |

| GC20008MC1 | GC300C10AC1K | GC30008LF3G | GC30015NWTK | GC40010ALF3WGK | GC60025MLNG |

| GC20008MC1K | GC300C10AC1W | GC30008LF3GK | GC30015AC1 | GC40010ALN | GC60025MLNGK |

| GC20008MC1W | GC300C08AC1W | GC30008LF3WG | GC30015AC1K | GC40010ALNG | GC60025MLNK |

| GC20008MF1 | GC300C15AC1W | GC30008LF3WGK | GC30015AC1W | GC40010ALNGK | GC60025MLNT |

| GC20008MF1K | GC300C10AC1WK | GC30008LN | GC30015AF1 | GC40010ALNK | GC60025MLNTK |

| GC20008MF1W | GC300C08AC1WK | GC30008LNG | GC30015AF1W | GC40010ALNT | GC60025MLNW |

| GC20008MF1WK | GC300C15AC1WK | GC30008LNGK | GC30015C1 | GC40010ALNTK | GC60025MLNWG |

| GC20006C1 | GC300C10AF1 | GC30008LNK | GC30015C1W | GC40010ALNW | GC60025MLNWGK |

| GC20006C1W | GC300C08AF1 | GC30008LNT | GC30015F1 | GC40010ALNWG | GC60025MLNWK |

| GC20006F1 | GC300C15AF1 | GC30008LNTK | GC30015F1K | GC40010ALNWGK | GC60025MLNWT |

| GC20006F1K | GC300C10AF1K | GC30008LNW | GC30015F1W | GC40010ALNWK | GC60025MLNWTK |

| GC20006F1W | GC300C08AF1K | GC30008LNWG | GC30015MF1WK | GC40010ALNWT | GC60025MN |

| GC20006MC1 | GC300C15AF1K | GC30008LNWGK | GC30015MC1 | GC40010ALNWTK | GC60025MNG |

| GC20006MC1W | GC300C10AF1W | GC30008LNWK | GC30015MF1K | GC40010AN | GC60025MNGK |

| GC20006MC1WK | GC300C08AF1W | GC30008LNWT | GC30015MF1W | GC40010ANG | GC60025MNK |

| GC20006MF1 | GC300C15AF1W | GC30008LNWTK | GC30015MF1 | GC40010ANGK | GC60025MNT |

| GC20006MF1W | GC300C10AF1WK | GC30008MC1WK | GC40015AC1WK | GC40010ANK | GC60025MNTK |

| GC20006MF1WK | GC300C08AF1WK | GC30008MC2T | GC40015AC2T | GC40010ANT | GC60025MNW |

| GC200-08-M-C1-W-K | GC300C15AF1WK | GC30008MC2TK | GC40015AC2TK | GC40010ANTK | GC60025MNWG |

| GC200C06MNWK | GC300C10C1 | GC30008MC2WT | GC40015AC2WT | GC40010ANW | GC60025MNWGK |

| GC200C08MN | GC300C08C1 | GC30008MC2WTK | GC40015AC2WTK | GC40010ANWG | GC60025MNWK |

| GC200C06LNG | GC300C15C1 | GC30008MC3G | GC40015AC3G | GC40010ANWGK | GC60025MNWT |

| GC200C06NT | GC300C10C1K | GC30008MC3GK | GC40015AC3GK | GC40010ANWK | GC60025MNWTK |

| GC200C08MNWGK | GC300C08C1K | GC30008MC3WG | GC40015AC3WG | GC40010ANWT | GC60025N |

| GC200C06LNWK | GC300C15C1K | GC30008MC3WGK | GC40015AC3WGK | GC40010ANWTK | GC60025NG |

| GC200C08LN | GC300C10C1W | GC30008MF1WK | GC40015AF1WK | GC40010C1WK | GC60025NGK |

| GC200C08NT | GC300C08C1W | GC30008MF2T | GC40015AF2T | GC40010C2T | GC60025NK |

| GC200C06MLNTK | GC300C15C1W | GC30008MF2TK | GC40015AF2TK | GC40010C2TK | GC60025NT |

| GC200C08LNWGK | GC300C10C1WK | GC30008MF2WT | GC40015AF2WT | GC40010C2WT | GC60025NTK |

| GC200C06MNG | GC300C08C1WK | GC30008MF2WTK | GC40015AF2WTK | GC40010C2WTK | GC60025NW |

| GC200C08MLNT | GC300C15C1WK | GC30008MF3G | GC40015AF3G | GC40010C3G | GC60025NWG |

| GC200C06MNWT | GC300C10F1 | GC30008MF3GK | GC40015AF3GK | GC40010C3GK | GC60025NWGK |

| GC200C08MNG | GC300C08F1 | GC30008MF3WG | GC40015AF3WG | GC40010C3WG | GC60025NWK |

| GC200C06LNGK | GC300C15F1 | GC30008MF3WGK | GC40015AF3WGK | GC40010C3WGK | GC60025NWT |

| GC200C06NTK | GC300C10F1K | GC30008MLC1 | GC40015ALC1 | GC40010F1WK | GC60025NWTK |

| GC200C08MNWK | GC300C08F1K | GC30008MLC1K | GC40015ALC1K | GC40010F2T | GC60020AC1WK |

| GC200C06LNWT | GC300C15F1K | GC30008MLC1W | GC40015ALC1W | GC40010F2TK | GC60020AC2T |

| GC200C08LNG | GC300C15F1W | GC30008MLC1WK | GC40015ALC1WK | GC40010F2WT | GC60020AC2TK |

| GC200C08NTK | GC300C10F1W | GC30008MLC2T | GC40015ALC2T | GC40010F2WTK | GC60020AC2WT |

| GC200C06MLNW | GC300C08F1W | GC30008MLC2TK | GC40015ALC2TK | GC40010F3G | GC60020AC2WTK |

| GC200C08LNWK | GC300C15F1WK | GC30008MLC2WT | GC40015ALC2WT | GC40010F3GK | GC60020AC3G |

| GC200C06MNGK | GC300C10F1WK | GC30008MLC2WTK | GC40015ALC2WTK | GC40010F3WG | GC60020AC3GK |

| GC200C08MLNTK | GC300C08F1WK | GC30008MLC3G | GC40015ALC3G | GC40010F3WGK | GC60020AC3WG |

| GC200C06MNWTK | GC300C15MC1 | GC30008MLC3GK | GC40015ALC3GK | GC40010LC1 | GC60020AC3WGK |

| GC200C08MNGK | GC300C10MC1 | GC30008MLC3WG | GC40015ALC3WG | GC40010LC1K | GC60020AF1K |

| GC200C06LNK | GC300C08MC1 | GC30008MLC3WGK | GC40015ALC3WGK | GC40010LC1W | GC60020AF1WK |

| GC200C06NW | GC300C15MC1K | GC30008MLF1 | GC40015ALF1 | GC40010LC1WK | GC60020AF2T |

| GC200C08MNWT | GC300C10MC1K | GC30008MLF1K | GC40015ALF1K | GC40010LC2T | GC60020AF2TK |

| GC200C06LNWTK | GC300C08MC1K | GC30008MLF1W | GC40015ALF1W | GC40010LC2TK | GC60020AF2WT |

| GC200C08LNGK | GC300C15MC1W | GC30008MLF1WK | GC40015ALF1WK | GC40010LC2WT | GC60020AF2WTK |

| GC200C08NW | GC300C10MC1W | GC30008MLF2T | GC40015ALF2T | GC40010LC2WTK | GC60020AF3G |

| GC200C06MLNWG | GC300C08MC1W | GC30008MLF2TK | GC40015ALF2TK | GC40010LC3G | GC60020AF3GK |

| GC200C08LNWT | GC300C15MC1WK | GC30008MLF2WT | GC40015ALF2WT | GC40010LC3GK | GC60020AF3WG |

| GC200C06MNK | GC300C10MC1WK | GC30008MLF2WTK | GC40015ALF2WTK | GC40010LC3WG | GC60020AF3WGK |

| GC200C08MLNW | GC300C08MC1WK | GC30008MLF3G | GC40015ALF3G | GC40010LC3WGK | GC60020ALC1 |

| GC200C06N | GC300C15MF1 | GC30008MLF3GK | GC40015ALF3GK | GC40010LF1 | GC60020ALC1K |

| GC200C08MNK | GC300C10MF1 | GC30008MLF3WG | GC40015ALF3WG | GC40010LF1K | GC60020ALC1W |

| GC200C06LNT | GC300C08MF1 | GC30008MLF3WGK | GC40015ALF3WGK | GC40010LF1W | GC60020ALC1WK |

| GC200C06NWG | GC300C15MF1K | GC30008MLN | GC40015ALN | GC40010LF1WK | GC60020ALC2T |

| GC200C08MNWTK | GC300C10MF1K | GC30008MLNG | GC40015ALNG | GC40010LF2T | GC60020ALC2TK |

| GC200C06MLN | GC300C08MF1K | GC30008MLNGK | GC40015ALNGK | GC40010LF2TK | GC60020ALC2WT |

| GC200C08LNK | GC300C10MF1W | GC30008MLNK | GC40015ALNK | GC40010LF2WT | GC60020ALC2WTK |

| GC200C08NWG | GC300C08MF1W | GC30008MLNT | GC40015ALNT | GC40010LF2WTK | GC60020ALC3G |

| GC200C06MLNWGK | GC300C15MF1W | GC30008MLNTK | GC40015ALNTK | GC40010LF3G | GC60020ALC3GK |

| GC200C08LNWTK | GC300C10MF1WK | GC30008MLNW | GC40015ALNW | GC40010LF3GK | GC60020ALC3WG |

| GC200C06MNT | GC300C08MF1WK | GC30008MLNWG | GC40015ALNWG | GC40010LF3WG | GC60020ALC3WGK |

| GC200C08MLNWG | GC300C15MF1WK | GC30008MLNWGK | GC40015ALNWGK | GC40010LF3WGK | GC60020ALF1 |

| GC200C06NG | GC300C15F2T | GC30008MLNWK | GC40015ALNWK | GC40010LN | GC60020ALF1K |

| GC200C08MNT | GC300C15F2TK | GC30008MLNWT | GC40015ALNWT | GC40010LNG | GC60020ALF1W |

| GC200C06LNTK | GC300C15F2WT | GC30008MLNWTK | GC40015ALNWTK | GC40010LNGK | GC60020ALF1WK |

| GC200C06NWGK | GC300C15F2WTK | GC30008MN | GC40015AN | GC40010LNK | GC60020ALF2T |

| GC200C08N | GC300C15F3G | GC30008MNG | GC40015ANG | GC40010LNT | GC60020ALF2TK |

| GC200C06MLNG | GC300C15F3GK | GC30008MNGK | GC40015ANGK | GC40010LNTK | GC60020ALF2WT |

| GC200C08LNT | GC300C15F3WG | GC30008MNK | GC40015ANK | GC40010LNW | GC60020ALF2WTK |

| GC200C08NWGK | GC300C15F3WGK | GC30008MNT | GC40015ANT | GC40010LNWG | GC60020ALF3G |

| GC200C06MLNWK | GC300C15C2T | GC30008MNTK | GC40015ANTK | GC40010LNWGK | GC60020ALF3GK |

| GC200C08MLN | GC300C15C2TK | GC30008MNW | GC40015ANW | GC40010LNWK | GC60020ALF3WG |

| GC200C06MNTK | GC300C15C2WT | GC30008MNWG | GC40015ANWG | GC40010LNWT | GC60020ALF3WGK |

| GC200C08MLNWGK | GC300C15C2WTK | GC30008MNWGK | GC40015ANWGK | GC40010LNWTK | GC60020ALN |

| GC200C06MNW | GC300C15C3G | GC30008MNWK | GC40015ANWK | GC40010MC1K | GC60020ALNG |

| GC200C08MLNWK | GC300C15C3GK | GC30008MNWT | GC40015ANWT | GC40010MC1WK | GC60020ALNGK |

| GC200C08MNTK | GC300C15C3WG | GC30008MNWTK | GC40015ANWTK | GC40010MC2T | GC60020ALNK |

| GC200C06LNW | GC300C15C3WGK | GC30008N | GC40015C1WK | GC40010MC2TK | GC60020ALNT |

| GC200C06NWK | GC300C15LF1 | GC30008NG | GC40015C2T | GC40010MC2WT | GC60020ALNTK |

| GC200C08NG | GC300C15LF1K | GC30008NGK | GC40015C2TK | GC40010MC2WTK | GC60020ALNW |

| GC200C06MLNGK | GC300C15LF1W | GC30008NK | GC40015C2WT | GC40010MC3G | GC60020ALNWG |

| GC200C08LNTK | GC300C15LF1WK | GC30008NT | GC40015C2WTK | GC40010MC3GK | GC60020ALNWGK |

| GC200C08NWK | GC300C15LF2T | GC30008NTK | GC40015C3G | GC40010MC3WG | GC60020ALNWK |

| GC200C06MLNWT | GC300C15LF2TK | GC30008NW | GC40015C3GK | GC40010MC3WGK | GC60020ALNWT |

| GC200C08MLNG | GC300C15LF2WT | GC30008NWG | GC40015C3WG | GC40010MF1WK | GC60020ALNWTK |

| GC200C06MNWG | GC300C15LF2WTK | GC30008NWGK | GC40015C3WGK | GC40010MF2T | GC60020AN |

| GC200C08MLNWT | GC300C15LF3G | GC30008NWK | GC40015F1WK | GC40010MF2TK | GC60020ANG |

| GC200C06NGK | GC300C15LF3GK | GC30008NWT | GC40015F2T | GC40010MF2WT | GC60020ANGK |

| GC200C08MNW | GC300C15LF3WG | GC30008NWTK | GC40015F2TK | GC40010MF2WTK | GC60020ANK |

| GC200C06LNWG | GC300C15LF3WGK | GC30008AC1 | GC40015F2WT | GC40010MF3G | GC60020ANT |

| GC200C06NWT | GC300C15LC1 | GC30008AC1K | GC40015F2WTK | GC40010MF3GK | GC60020ANTK |

| GC200C08NGK | GC300C15LC1K | GC30008AC1W | GC40015F3G | GC40010MF3WG | GC60020ANW |

| GC200C06MLNK | GC300C15LC1W | GC30008AC1WK | GC40015F3GK | GC40010MF3WGK | GC60020ANWG |

| GC200C08LNW | GC300C15LC1WK | GC30008AF1 | GC40015F3WG | GC40010MLC1 | GC60020ANWGK |

| GC200C08NWT | GC300C15LC2T | GC30008AF1K | GC40015F3WGK | GC40010MLC1K | GC60020ANWK |

| GC200C06MLNWTK | GC300C15LC2TK | GC30008AF1W | GC40015LC1 | GC40010MLC1W | GC60020ANWT |

| GC200C08MLNGK | GC300C15LC2WT | GC30008C1 | GC40015LC1K | GC40010MLC1WK | GC60020ANWTK |

| GC200C06MNWGK | GC300C15LC2WTK | GC30008C1K | GC40015LC1W | GC40010MLC2T | GC60020C1K |

| GC200C08MLNWTK | GC300C15LC3G | GC30008C1W | GC40015LC1WK | GC40010MLC2TK | GC60020C1WK |

| GC200C06LN | GC300C15LC3GK | GC30008F1 | GC40015LC2T | GC40010MLC2WT | GC60020C2T |

| GC200C06NK | GC300C15LC3WG | GC30008F1K | GC40015LC2TK | GC40010MLC2WTK | GC60020C2TK |

| GC200C08MNWG | GC300C15LC3WGK | GC30008F1W | GC40015LC2WT | GC40010MLC3G | GC60020C2WT |

| GC200C06LNWGK | GC300C15MF2T | GC30008F1WK | GC40015LC2WTK | GC40010MLC3GK | GC60020C2WTK |

| GC200C06NWTK | GC300C15MF2TK | GC30008MC1 | GC40015LC3G | GC40010MLC3WG | GC60020C3G |

| GC200C08NK | GC300C15MF2WT | GC30008MC1K | GC40015LC3GK | GC40010MLC3WGK | GC60020C3GK |

| GC200C06MLNT | GC300C15MF2WTK | GC30008MC1W | GC40015LC3WG | GC40010MLF1 | GC60020C3WG |

| GC200C08LNWG | GC300C15MF3G | GC30008MF1 | GC40015LC3WGK | GC40010MLF1K | GC60020C3WGK |

| GC200C08NWTK | GC300C15MF3GK | GC30008MF1K | GC40015LF1 | GC40010MLF1W | GC60020F1K |

| GC200C06MN | GC300C15MF3WG | GC30008MF1W | GC40015LF1K | GC40010MLF1WK | GC60020F1WK |

| GC200C08MLNK | GC300C15MF3WGK | GC30010AC2T | GC40015LF1W | GC40010MLF2T | GC60020F2T |

| GC200C06C1 | GC300C15MC2T | GC30010AC2TK | GC40015LF1WK | GC40010MLF2TK | GC60020F2TK |

| GC200C06C1K | GC300C15MC2TK | GC30010AC2WT | GC40015LF2T | GC40010MLF2WT | GC60020F2WT |

| GC200C06C1W | GC300C15MC2WT | GC30010AC2WTK | GC40015LF2TK | GC40010MLF2WTK | GC60020F2WTK |

| GC200C06C1WK | GC300C15MC2WTK | GC30010AC3G | GC40015LF2WT | GC40010MLF3G | GC60020F3G |

| GC200C06F1 | GC300C15MC3G | GC30010AC3GK | GC40015LF2WTK | GC40010MLF3GK | GC60020F3GK |

| GC200C06F1K | GC300C15MC3GK | GC30010AC3WG | GC40015LF3G | GC40010MLF3WG | GC60020F3WG |

| GC200C06F1W | GC300C15MC3WG | GC30010AC3WGK | GC40015LF3GK | GC40010MLF3WGK | GC60020F3WGK |

| GC200C06F1WK | GC300C15MC3WGK | GC30010AF2T | GC40015LF3WG | GC40010MLN | GC60020LC1 |

| GC200C06MC1 | GC300C15MLF1 | GC30010AF2TK | GC40015LF3WGK | GC40010MLNG | GC60020LC1K |

| GC200C06MC1K | GC300C15MLF1K | GC30010AF2WT | GC40015LN | GC40010MLNGK | GC60020LC1W |

| GC200C06MC1W | GC300C15MLF1W | GC30010AF2WTK | GC40015LNG | GC40010MLNK | GC60020LC1WK |

| GC200C06MC1WK | GC300C15MLF1WK | GC30010AF3G | GC40015LNGK | GC40010MLNT | GC60020LC2T |

| GC200C06MF1 | GC300C15MLF2T | GC30010AF3GK | GC40015LNK | GC40010MLNTK | GC60020LC2TK |

| GC200C06MF1K | GC300C15MLF2TK | GC30010AF3WG | GC40015LNT | GC40010MLNW | GC60020LC2WT |

| GC200C06MF1W | GC300C15MLF2WT | GC30010AF3WGK | GC40015LNTK | GC40010MLNWG | GC60020LC2WTK |

| GC200C06MF1WK | GC300C15MLF2WTK | GC30010ALC1 | GC40015LNW | GC40010MLNWGK | GC60020LC3G |

| GC200C08C1 | GC300C15MLF3G | GC30010ALC1K | GC40015LNWG | GC40010MLNWK | GC60020LC3GK |

| GC200C08C1K | GC300C15MLF3GK | GC30010ALC1W | GC40015LNWGK | GC40010MLNWT | GC60020LC3WG |

| GC200C08C1W | GC300C15MLF3WG | GC30010ALC1WK | GC40015LNWK | GC40010MLNWTK | GC60020LC3WGK |

| GC200C08C1WK | GC300C15MLF3WGK | GC30010ALC2T | GC40015LNWT | GC40010MN | GC60020LF1 |

| GC200C08F1 | GC300C15MLC1 | GC30010ALC2TK | GC40015LNWTK | GC40010MNG | GC60020LF1K |

| GC200C08F1K | GC300C15MLC1K | GC30010ALC2WT | GC40015MC1K | GC40010MNGK | GC60020LF1W |

| GC200C08F1W | GC300C15MLC1W | GC30010ALC2WTK | GC40015MC1WK | GC40010MNK | GC60020LF1WK |

| GC200C08F1WK | GC300C15MLC1WK | GC30010ALC3G | GC40015MC2T | GC40010MNT | GC60020LF2T |

| GC200C08MC1 | GC300C15MLC2T | GC30010ALC3GK | GC40015MC2TK | GC40010MNTK | GC60020LF2TK |

| GC200C08MC1K | GC300C15MLC2TK | GC30010ALC3WG | GC40015MC2WT | GC40010MNW | GC60020LF2WT |

| GC200C08MC1W | GC300C15MLC2WT | GC30010ALC3WGK | GC40015MC2WTK | GC40010MNWG | GC60020LF2WTK |

| GC200C08MC1WK | GC300C15MLC2WTK | GC30010ALF1 | GC40015MC3G | GC40010MNWGK | GC60020LF3G |

| GC200C08MF1 | GC300C15MLC3G | GC30010ALF1K | GC40015MC3GK | GC40010MNWK | GC60020LF3GK |

| GC200C08MF1K | GC300C15MLC3GK | GC30010ALF1W | GC40015MC3WG | GC40010MNWT | GC60020LF3WG |

| GC200C08MF1W | GC300C15MLC3WG | GC30010ALF1WK | GC40015MC3WGK | GC40010MNWTK | GC60020LF3WGK |

| GC200C08MF1WK | GC300C15MLC3WGK | GC30010ALF2T | GC40015MF1K | GC40010N | GC60020LN |

| GC200C08F2T | GC300C15AF2T | GC30010ALF2TK | GC40015MF2T | GC40010NG | GC60020LNG |

| GC200C08F2TK | GC300C15AF2TK | GC30010ALF2WT | GC40015MF2TK | GC40010NGK | GC60020LNGK |

| GC200C08F2WT | GC300C15AF2WT | GC30010ALF2WTK | GC40015MF2WT | GC40010NK | GC60020LNK |

| GC200C08F2WTK | GC300C15AF2WTK | GC30010ALF3G | GC40015MF2WTK | GC40010NT | GC60020LNT |

| GC200C08F3G | GC300C15AF3G | GC30010ALF3GK | GC40015MF3G | GC40010NTK | GC60020LNTK |

| GC200C08F3GK | GC300C15AF3GK | GC30010ALF3WG | GC40015MF3GK | GC40010NW | GC60020LNW |

| GC200C08F3WG | GC300C15AF3WG | GC30010ALF3WGK | GC40015MF3WG | GC40010NWG | GC60020LNWG |

| GC200C08F3WGK | GC300C15AF3WGK | GC30010ALN | GC40015MF3WGK | GC40010NWGK | GC60020LNWGK |

| GC200C08C2T | GC300C15AC2T | GC30010ALNG | GC40015MLC1 | GC40010NWK | GC60020LNWK |

| GC200C08C2TK | GC300C15AC2TK | GC30010ALNGK | GC40015MLC1K | GC40010NWT | GC60020LNWT |

| GC200C08C2WT | GC300C15AC2WT | GC30010ALNK | GC40015MLC1W | GC40010NWTK | GC60020LNWTK |

| GC200C08C2WTK | GC300C15AC2WTK | GC30010ALNT | GC40015MLC1WK | GC40010AC1 | GC60020MC1K |

| GC200C08C3G | GC300C15AC3G | GC30010ALNTK | GC40015MLC2T | GC40010AC1K | GC60020MC1WK |

| GC200C08C3GK | GC300C15AC3GK | GC30010ALNW | GC40015MLC2TK | GC40010AC1W | GC60020MC2T |

| GC200C08C3WG | GC300C15AC3WG | GC30010ALNWG | GC40015MLC2WT | GC40010AF1 | GC60020MC2TK |

| GC200C08C3WGK | GC300C15AC3WGK | GC30010ALNWGK | GC40015MLC2WTK | GC40010AF1K | GC60020MC2WT |

| GC200C08LF1 | GC300C15ALF1 | GC30010ALNWK | GC40015MLC3G | GC40010C1 | GC60020MC2WTK |

| GC200C08LF1K | GC300C15ALF1K | GC30010ALNWT | GC40015MLC3GK | GC40010C1K | GC60020MC3G |

| GC200C08LF1W | GC300C15ALF1W | GC30010ALNWTK | GC40015MLC3WG | GC40010C1W | GC60020MC3GK |

| GC200C08LF1WK | GC300C15ALF1WK | GC30010AN | GC40015MLC3WGK | GC40010F1 | GC60020MC3WG |

| GC200C08LF2T | GC300C15ALF2T | GC30010ANG | GC40015MLF1 | GC40010F1K | GC60020MC3WGK |

| GC200C08LF2TK | GC300C15ALF2TK | GC30010ANGK | GC40015MLF1K | GC40010F1W | GC60020MF1K |

| GC200C08LF2WT | GC300C15ALF2WT | GC30010ANK | GC40015MLF1W | GC40010MC1 | GC60020MF1WK |

| GC200C08LF2WTK | GC300C15ALF2WTK | GC30010ANT | GC40015MLF1WK | GC40010MC1W | GC60020MF2T |

| GC200C08LF3G | GC300C15ALF3G | GC30010ANTK | GC40015MLF2T | GC40010MF1 | GC60020MF2TK |

| GC200C08LF3GK | GC300C15ALF3GK | GC30010ANW | GC40015MLF2TK | GC40010MF1K | GC60020MF2WT |

| GC200C08LF3WG | GC300C15ALF3WG | GC30010ANWG | GC40015MLF2WT | GC40010MF1W | GC60020MF2WTK |

| GC200C08LF3WGK | GC300C15ALF3WGK | GC30010ANWGK | GC40015MLF2WTK | GC40015AC1 | GC60020MF3G |

| GC200C08LC1 | GC300C15ALC1 | GC30010ANWK | GC40015MLF3G | GC40015AC1K | GC60020MF3GK |

| GC200C08LC1K | GC300C15ALC1K | GC30010ANWT | GC40015MLF3GK | GC40015AC1W | GC60020MF3WG |

| GC200C08LC1W | GC300C15ALC1W | GC30010ANWTK | GC40015MLF3WG | GC40015AF1 | GC60020MF3WGK |

| GC200C08LC1WK | GC300C15ALC1WK | GC30010C2T | GC40015MLF3WGK | GC40015AF1K | GC60020MLC1 |

| GC200C08LC2T | GC300C15ALC2T | GC30010C2TK | GC40015MLN | GC40015AF1W | GC60020MLC1K |

| GC200C08LC2TK | GC300C15ALC2TK | GC30010C2WT | GC40015MLNG | GC40015C1 | GC60020MLC1W |

| GC200C08LC2WT | GC300C15ALC2WT | GC30010C2WTK | GC40015MLNGK | GC40015C1K | GC60020MLC1WK |

| GC200C08LC2WTK | GC300C15ALC2WTK | GC30010C3G | GC40015MLNK | GC40015C1W | GC60020MLC2T |

| GC200C08LC3G | GC300C15ALC3G | GC30010C3GK | GC40015MLNT | GC40015F1 | GC60020MLC2TK |

| GC200C08LC3GK | GC300C15ALC3GK | GC30010C3WG | GC40015MLNTK | GC40015F1K | GC60020MLC2WT |

| GC200C08LC3WG | GC300C15ALC3WG | GC30010C3WGK | GC40015MLNW | GC40015F1W | GC60020MLC2WTK |

| GC200C08LC3WGK | GC300C15ALC3WGK | GC30010F1WK | GC40015MLNWG | GC40015MC1 | GC60020MLC3G |

| GC200C08MF2T | GC300C08F2T | GC30010F2T | GC40015MLNWGK | GC40015MC1W | GC60020MLC3GK |

| GC200C08MF2TK | GC300C08F2TK | GC30010F2TK | GC40015MLNWK | GC40015MF1 | GC60020MLC3WG |

| GC200C08MF2WT | GC300C08F2WT | GC30010F2WT | GC40015MLNWT | GC40015MF1W | GC60020MLC3WGK |

| GC200C08MF2WTK | GC300C08F2WTK | GC30010F2WTK | GC40015MLNWTK | GC40015MF1WK | GC60020MLF1 |

| GC200C08MF3G | GC300C08F3G | GC30010F3G | GC40015MN | GC400C10F2T | GC60020MLF1K |

| GC200C08MF3GK | GC300C08F3GK | GC30010F3GK | GC40015MNG | GC400C10F2TK | GC60020MLF1W |

| GC200C08MF3WG | GC300C08F3WG | GC30010F3WG | GC40015MNGK | GC400C10F2WT | GC60020MLF1WK |

| GC200C08MF3WGK | GC300C08F3WGK | GC30010F3WGK | GC40015MNK | GC400C10F2WTK | GC60020MLF2T |

| GC200C08MC2T | GC300C08C2T | GC30010LC1 | GC40015MNT | GC400C10F3G | GC60020MLF2TK |

| GC200C08MC2TK | GC300C08C2TK | GC30010LC1K | GC40015MNTK | GC400C10F3GK | GC60020MLF2WT |

| GC200C08MC2WT | GC300C08C2WT | GC30010LC1W | GC40015MNW | GC400C10F3WG | GC60020MLF2WTK |

| GC200C08MC2WTK | GC300C08C2WTK | GC30010LC1WK | GC40015MNWG | GC400C10F3WGK | GC60020MLF3G |

| GC200C08MC3G | GC300C08C3G | GC30010LC2T | GC40015MNWGK | GC400C10C2T | GC60020MLF3GK |

| GC200C08MC3GK | GC300C08C3GK | GC30010LC2TK | GC40015MNWK | GC400C10C2TK | GC60020MLF3WG |

| GC200C08MC3WG | GC300C08C3WG | GC30010LC2WT | GC40015MNWT | GC400C10C2WT | GC60020MLF3WGK |

| GC200C08MC3WGK | GC300C08C3WGK | GC30010LC2WTK | GC40015MNWTK | GC400C10C2WTK | GC60020MLN |

| GC200C08MLF1 | GC300C08LF1 | GC30010LC3G | GC40015N | GC400C10C3G | GC60020MLNG |

| GC200C08MLF1K | GC300C08LF1K | GC30010LC3GK | GC40015NG | GC400C10C3GK | GC60020MLNGK |

| GC200C08MLF1W | GC300C08LF1W | GC30010LC3WG | GC40015NGK | GC400C10C3WG | GC60020MLNK |

| GC200C08MLF1WK | GC300C08LF1WK | GC30010LC3WGK | GC40015NK | GC400C10C3WGK | GC60020MLNT |

| GC200C08MLF2T | GC300C08LF2T | GC30010LF1 | GC40015NT | GC400C10LF1 | GC60020MLNTK |

| GC200C08MLF2TK | GC300C08LF2TK | GC30010LF1K | GC40015NTK | GC400C10LF1K | GC60020MLNW |

| GC200C08MLF2WT | GC300C08LF2WT | GC30010LF1W | GC40015NW | GC400C10LF1W | GC60020MLNWG |

| GC200C08MLF2WTK | GC300C08LF2WTK | GC30010LF1WK | GC40015NWG | GC400C10LF1WK | GC60020MLNWGK |

| GC200C08MLF3G | GC300C08LF3G | GC30010LF2T | GC40015NWGK | GC400C10LF2T | GC60020MLNWK |

| GC200C08MLF3GK | GC300C08LF3GK | GC30010LF2TK | GC40015NWK | GC400C10LF2TK | GC60020MLNWT |

| GC200C08MLF3WG | GC300C08LF3WG | GC30010LF2WT | GC40015NWT | GC400C10LF2WT | GC60020MLNWTK |

| GC200C08MLF3WGK | GC300C08LF3WGK | GC30010LF2WTK | GC40015NWTK | GC400C10LF2WTK | GC60020MN |

| GC200C08MLC1 | GC300C08LC1 | GC30010LF3G | GC400C15F2T | GC400C10LF3G | GC60020MNG |

| GC200C08MLC1K | GC300C08LC1K | GC30010LF3GK | GC400C15F2TK | GC400C10LF3GK | GC60020MNGK |

| GC200C08MLC1W | GC300C08LC1W | GC30010LF3WG | GC400C15F2WT | GC400C10LF3WG | GC60020MNK |

| GC200C08MLC1WK | GC300C08LC1WK | GC30010LF3WGK | GC400C15F2WTK | GC400C10LF3WGK | GC60020MNT |

| GC200C08MLC2T | GC300C08LC2T | GC30010LN | GC400C15F3G | GC400C10LC1 | GC60020MNTK |

| GC200C08MLC2TK | GC300C08LC2TK | GC30010LNG | GC400C15F3GK | GC400C10LC1K | GC60020MNW |

| GC200C08MLC2WT | GC300C08LC2WT | GC30010LNGK | GC400C15F3WG | GC400C10LC1W | GC60020MNWG |

| GC200C08MLC2WTK | GC300C08LC2WTK | GC30010LNK | GC400C15F3WGK | GC400C10LC1WK | GC60020MNWGK |

| GC200C08MLC3G | GC300C08LC3G | GC30010LNT | GC400C15C2T | GC400C10LC2T | GC60020MNWK |

| GC200C08MLC3GK | GC300C08LC3GK | GC30010LNTK | GC400C15C2TK | GC400C10LC2TK | GC60020MNWT |

| GC200C08MLC3WG | GC300C08LC3WG | GC30010LNW | GC400C15C2WT | GC400C10LC2WT | GC60020MNWTK |

| GC200C08MLC3WGK | GC300C08LC3WGK | GC30010LNWG | GC400C15C2WTK | GC400C10LC2WTK | GC60020N |

| GC200C06F2T | GC300C08MF2T | GC30010LNWGK | GC400C15C3G | GC400C10LC3G | GC60020NG |

| GC200C06F2TK | GC300C08MF2TK | GC30010LNWK | GC400C15C3GK | GC400C10LC3GK | GC60020NGK |

| GC200C06F2WT | GC300C08MF2WT | GC30010LNWT | GC400C15C3WG | GC400C10LC3WG | GC60020NK |

| GC200C06F2WTK | GC300C08MF2WTK | GC30010LNWTK | GC400C15C3WGK | GC400C10LC3WGK | GC60020NT |

| GC200C06F3G | GC300C08MF3G | GC30010MC1WK | GC400C15LF1 | GC400C10ALN | GC60020NTK |

| GC200C06F3GK | GC300C08MF3GK | GC30010MC2T | GC400C15LF1K | GC400C10ALNG | GC60020NW |

| GC200C06F3WG | GC300C08MF3WG | GC30010MC2TK | GC400C15LF1W | GC400C10ALNGK | GC60020NWG |

| GC200C06F3WGK | GC300C08MF3WGK | GC30010MC2WT | GC400C15LF1WK | GC400C10ALNK | GC60020NWGK |

| GC200C06C2T | GC300C08MC2T | GC30010MC2WTK | GC400C15LF2T | GC400C10ALNT | GC60020NWK |

| GC200C06C2TK | GC300C08MC2TK | GC30010MC3G | GC400C15LF2TK | GC400C10ALNTK | GC60020NWT |

| GC200C06C2WT | GC300C08MC2WT | GC30010MC3GK | GC400C15LF2WT | GC400C10ALNW | GC60020NWTK |

| GC200C06C2WTK | GC300C08MC2WTK | GC30010MC3WG | GC400C15LF2WTK | GC400C10ALNWG | GC60025F1 |

| GC200C06C3G | GC300C08MC3G | GC30010MC3WGK | GC400C15LF3G | GC400C10ALNWGK | GC60025MC1 |

| GC200C06C3GK | GC300C08MC3GK | GC30010MF2T | GC400C15LF3GK | GC400C10ALNWK | GC60025MC1W |

| GC200C06C3WG | GC300C08MC3WG | GC30010MF2TK | GC400C15LF3WG | GC400C10ALNWT | GC60020AC1 |

| GC200C06C3WGK | GC300C08MC3WGK | GC30010MF2WT | GC400C15LF3WGK | GC400C10ALNWTK | GC60020AC1K |

| GC200C06LF1 | GC300C08MLF1 | GC30010MF2WTK | GC400C15LC1 | GC400C10AN | GC60020AC1W |

| GC200C06LF1K | GC300C08MLF1K | GC30010MF3G | GC400C15LC1K | GC400C10ANG | GC60020AF1 |

| GC200C06LF1W | GC300C08MLF1W | GC30010MF3GK | GC400C15LC1W | GC400C10ANGK | GC60020AF1W |

| GC200C06LF1WK | GC300C08MLF1WK | GC30010MF3WG | GC400C15LC1WK | GC400C10ANK | GC60020C1 |

| GC200C06LF2T | GC300C08MLF2T | GC30010MF3WGK | GC400C15LC2T | GC400C10ANT | GC60020C1W |

| GC200C06LF2TK | GC300C08MLF2TK | GC30010MLC1 | GC400C15LC2TK | GC400C10ANTK | GC60020F1 |

| GC200C06LF2WT | GC300C08MLF2WT | GC30010MLC1K | GC400C15LC2WT | GC400C10ANW | GC60020F1W |

| GC200C06LF2WTK | GC300C08MLF2WTK | GC30010MLC1W | GC400C15LC2WTK | GC400C10ANWG | GC60020MC1 |

| GC200C06LF3G | GC300C08MLF3G | GC30010MLC1WK | GC400C15LC3G | GC400C10ANWGK | GC60020MC1W |

| GC200C06LF3GK | GC300C08MLF3GK | GC30010MLC2T | GC400C15LC3GK | GC400C10ANWK | GC60020MF1 |

| GC200C06LF3WG | GC300C08MLF3WG | GC30010MLC2TK | GC400C15LC3WG | GC400C10ANWT | GC60020MF1W |

| GC200C06LF3WGK | GC300C08MLF3WGK | GC30010MLC2WT | GC400C15LC3WGK | GC400C10ANWTK | GC400C15MF2WTK |

| GC200C06LC1 | GC300C08MLC1 | GC30010MLC2WTK | GC400C15MF2T | GC400C10LN | GC30010MLC3WG |

| GC200C06LC1K | GC300C08MLC1K | GC30010MLC3G | GC400C15MF2TK | GC400C10LNG | GC300C08MLC1WK |

| GC200C06LC1W | GC300C08MLC1W | GC30010MLC3GK | GC400C15MF2WT | GC400C10LNGK | GC300C08MLC1WK |